Want to Know How Paishun Tests Fuel Line’s Permeability?

What is fuel permeation?

In an automotive area, permeation refers to how gases, vapors, or fluids pass through materials. Fuel vapor can permeate through fuel hoses or fuel lines. Hence, fuel hoses are made with materials that are meant to either lessen or completely prevent permeation.

Why a low permeability is so important to a rubber fuel hose?

-To Guarantee Safety: Fuel vapors are flammable and can pose a fire or explosion risk if they accumulate in the surroundings.

-For Environmental: Friendly.

-For Fuel Efficiency: By minimizing permeation, rubber fuel hoses can help maintain the integrity of the fuel system and optimize fuel consumption.

-Durability and Longevity: By maintaining low permeability, the rubber hose can retain its physical properties and ensure long-term durability.

Which rubber material would be the best choice for applications with prolonged exposure to oils?

For applications with prolonged exposure to oils, Fluorocarbon Rubber (FKM) is generally considered the best choice. FKM, also known as Viton®, offers excellent resistance to a wide range of oils, fuels, and chemicals. It has a high degree of oil resistance, making it suitable for long-term exposure to oils and petroleum-based fluids.

One of the methods to test permeability of rubber fuel hoses.

Sealing one end of the fuel hose and filling it with the fuel under test. The hose is then weighed at regular intervals over a specified duration. Any weight loss indicates fuel vapor permeation through the hose, and the permeation rate can be determined based on the weight loss over time.

Permeability Test on Paishun’s Fuel Line.

We use the above method to do the test, this test lasts for 1 month!

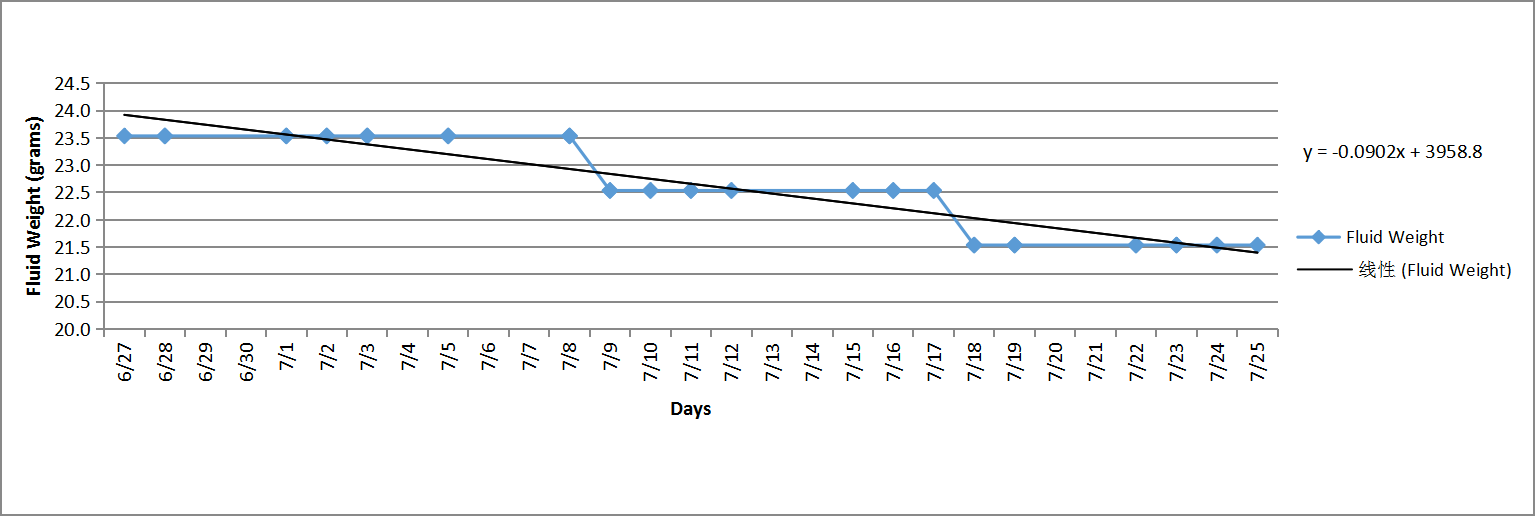

Hose 1: SAE J30R9 Fuel Line.

Standard Permeation Rate: 15 g/m2/day.

Test Result:

PR Using Linear Regression: 9.73 g/m2/day.

Average Daily Permeation Rate: 7.85 g/m2/day.

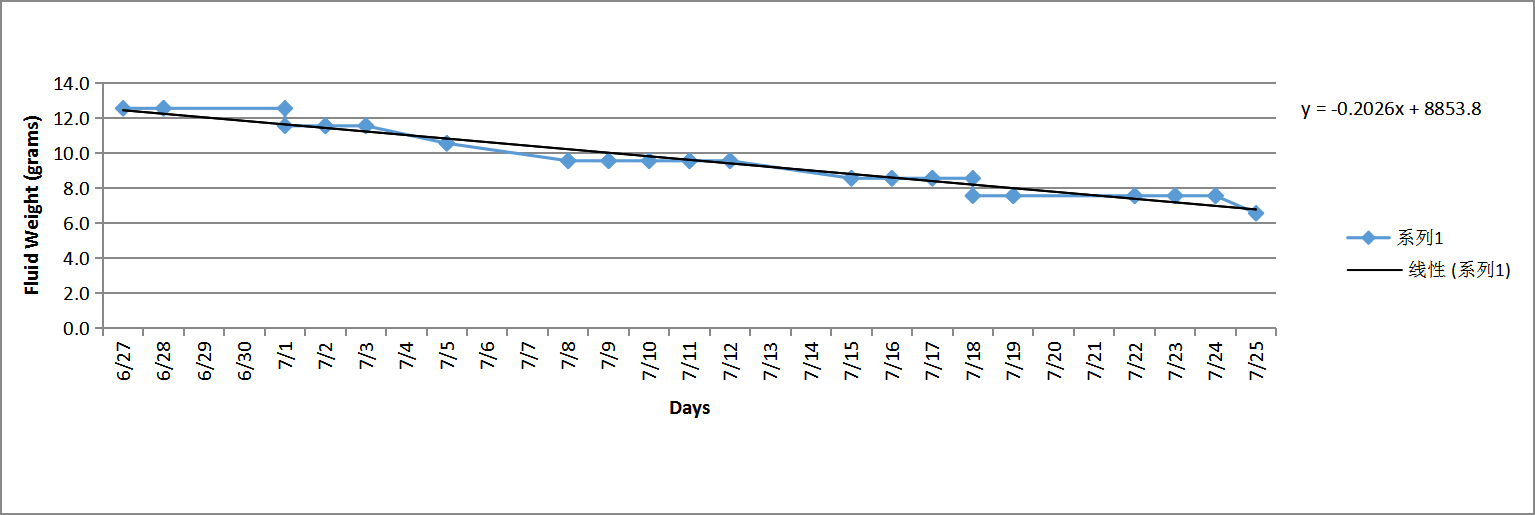

Hose 2: SAE J30R7 Fuel Line.

Standard Permeation Rate: 550 g/m2/day..

Test Result-

PR Using Linear Regression: 22.03 g/m2/day.

Average Daily Permeation Rate: 23.5 g/m2/day.

Paishun produces various rubber fuel hoses, SAE J30 series fuel line is one of the important sectors. The fuel line is made from material with excellent permeation resistance, which guarantees long usage life, and safety during application.

Please contact Paishun for more information! We may offer you our fuel hose samples for testing. Probably you would like our fuel hose, and let's start a long and stable collaboration!

Alice Jiang

WhatsApp: +86 159 6880 6735

Email: ps010@parshun.com

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China