Essential Tips for Storing Welding Hoses to Maximize Longevity

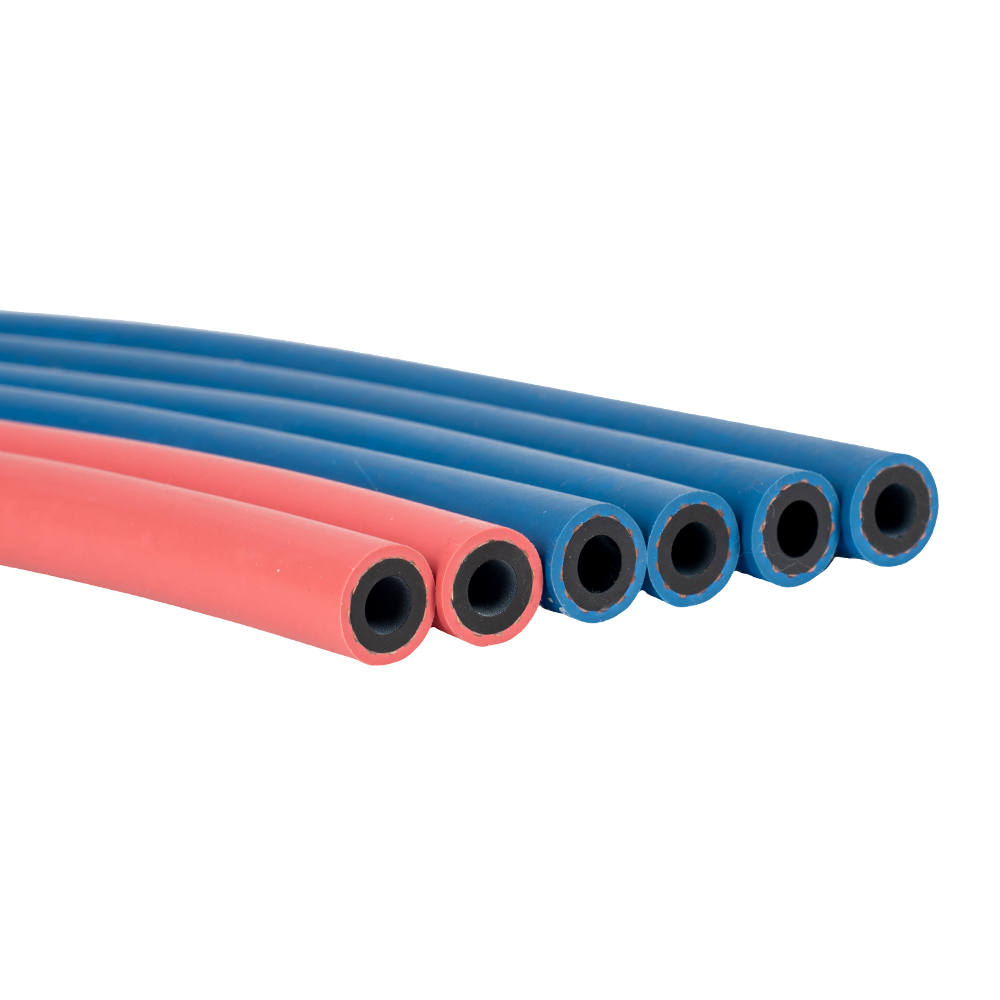

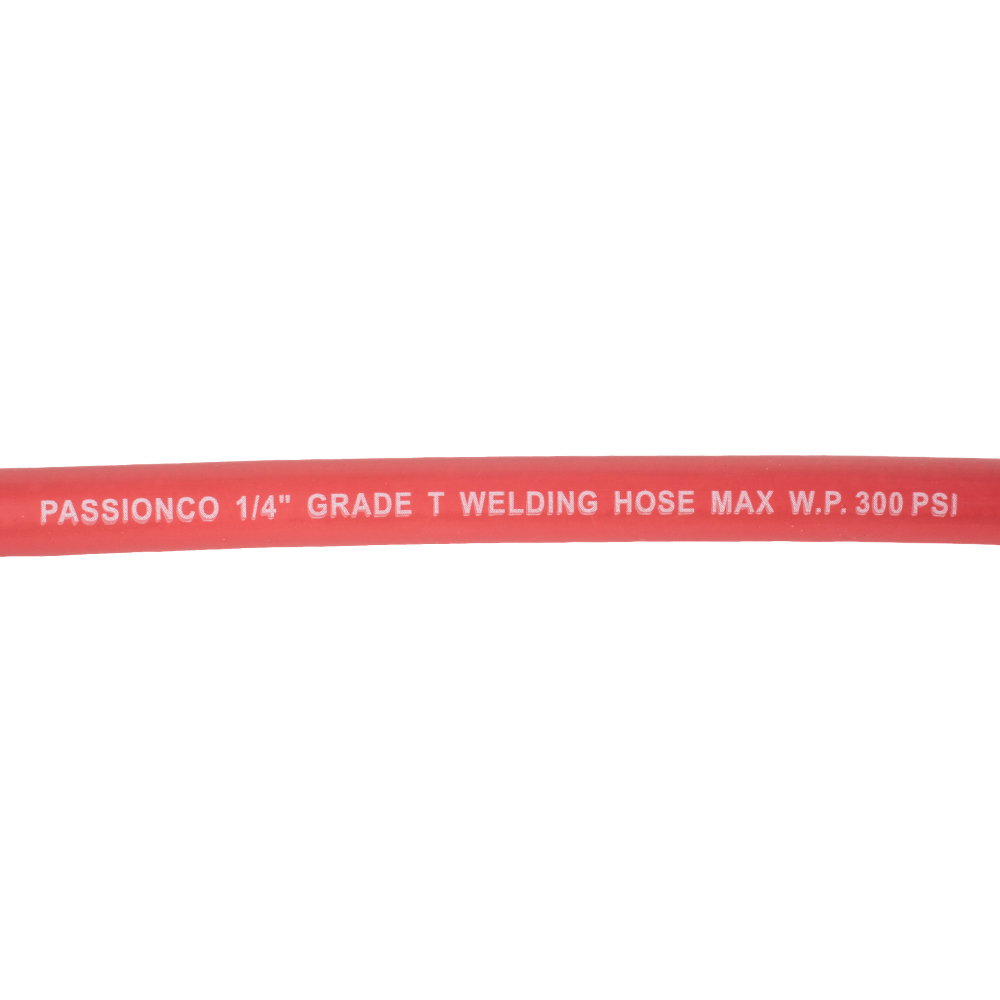

Welding hoses are an essential tool for various industries like automotive, construction, etc. They are used for welding different surfaces or objects and are a crucial component, so maximizing their longevity is important for ensuring safety. Proper handling of these hoses is vital for their performance. We will discuss the essential tips for storing welding hoses to maximize longevity in this blog by considering the instructions often given by welding hose suppliers. Below are a few tips for that:

The first essential tip for storing welding hoses is to protect them from sunlight. UV rays usually degrade hose materials, especially those designed by welding hose suppliers for light-duty applications, over a span of time. To protect them from damage, they should be stored in a cool place, away from sunlight, in some shelter, or protected by covers.

The second essential tip for storing welding hoses to maximize longevity is to store them off the ground at an elevated position. This will keep them away from absorbing moisture and lessen the damage caused by friction caused by contacting the rough surfaces.

The third essential tip for storing welding hoses to maximize longevity is to use a coil around the hose drum or reel, but it should not be tightened. Moreover, make sure not to give it sharp bends or kinks, messing with the shape given by the welding hose supplier, as this can weaken its structure over time. You can only bend it according to the recommended bending radius advised by the welding hose manufacturer for your PVC welding hose. If you bend it more than suggested, you may end up cracking it by causing stress points.

The fourth essential tip for storing welding hoses to maximize longevity is to consider temperature. Despite the fact that welding hoses have immunity against extreme conditions, they should not be exposed to both hot and cold extreme conditions, as it leaves an impact on the overall health of welding hoses.

The fifth essential tip for storing welding hoses to maximize longevity is to keep them dry. You can do this by draining all liquids from it if it is exposed to any fluid for transfer. To ensure complete draining out of fluid, you may also purge the hose with compressed air.

The sixth essential tip for storing welding hoses to maximize longevity is to store them in racks or hangers specifically designed for storing welding hoses. This is another effort to put them away from the ground to protect against any sort of irregular contact that can possibly cause damage.

The seventh essential tip for storing welding hoses to maximize longevity is to save them from cuts and abrasion. Despite all the protective measures already described, it is important to keep a check that they do not touch any abrasive surface or sharp edge that can cause this damage. If you see any twist or bend in them, you may pay attention to it.

The eighth essential tip for welding hose suppliers for storing welding hoses to maximize longevity is to rotate stocks in case of a large hose inventory. In most cases, welding hose suppliers stock new hoses and use them first, while the older ones get dumped down the pile. You need to follow the FIFO system, which is the first in, first out method, where you first use the welding hose that you brought first to make sure they do not degrade or age by staying unused.

The ninth essential tip for storing welding hoses to maximize longevity is to protect the welding hoses from all sorts of debris, dirt, and insects. Being a welding hose supplier, you can do so by plugging or capping the ends of the hose. This will not only prevent it from contamination but also ensure damage-free hose fittings. In fact, when you bring the hose, you need to clean it before storing it to remove all chemicals, dirt, and debris from it. This will provide ultimate safety from damage and will prevent contagion in storage.

The tenth essential tip for storing welding hoses to maximize longevity is to inspect the welding hose regularly. A periodic inspection is often suggested for the stored hoses to rule out the possibility of any sign of wear or tear, degradation, or damage. If you find any damaged hoses, you need to replace them immediately to avoid any potential failure in the future.

Another essential tip for storing welding hoses to maximize longevity is to select a high-quality reel in case you are using hose reels. The reel should be customized to the size and type of hose you are using. This will prevent the reel from any loss caused during retraction. The perfect size and type will help in maintaining a controlled rewind feature.

To ensure the longevity of hoses, you need to check them by pressure testing, where they are exposed to pressure to see if there are any leaks or not, occasionally. If you observe a drop in pressure, the reason could be any weak point or small puncture that demands attention.

There are some more practices for handling the hose safely. One of them is to avoid dragging it across sharp edges or rough surfaces. Doing otherwise will give punctures to the hose, compromising its performance. Another one to give special consideration to the use of suitable techniques for connection and disconnection of the hose from the equipment. The fittings need to be secure with the hose, but you should avoid over-tightening, which can destroy the ends of the hose.

When you get a welding hose, it is important to look for the guidelines mentioned by the welding hose manufacturer for storing and handling it, as they have a better idea about the protection of that particular hose. If stored effectively, it can enhance the longevity and integrity of welding hose, and you can enjoy better performance. You can ensure the reliability of these hoses by ensuring these practices.

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China