“A guide on selecting the right dry ice hose, covering factors like material, length, diameter, connection type, and key features.”

In the rapidly advancing world of industrial processes, the need for precision, efficiency, and safety has never been higher. One essential component that plays a critical role in industries such as food processing, medical storage, and cryogenics is the *Dry Ice Hose*. This advanced hose system is designed to handle the extreme temperatures and pressures associated with dry ice, offering unmatched reliability and versatility. In this article, we explore the significance of dry ice hoses, their applications, and why they are indispensable for modern industry.

What is Dry Ice and Why is it Used in Industry?

Dry ice, the solid form of carbon dioxide (CO₂), is widely used for its exceptional cooling properties. Unlike conventional ice, dry ice sublimates directly into gas without leaving any liquid behind, making it an ideal choice for a wide range of applications. It is commonly used for refrigeration during shipping, food processing, in medical facilities for preserving biological samples, and in cryogenic operations.

For industries dealing with dry ice, ensuring its safe and efficient transfer and application is paramount. This is where dry ice hoses come into play. These hoses are specifically engineered to withstand the extreme cold temperatures and pressures of CO₂ in its solid state, enabling smooth, reliable operation.

Key Features of Dry Ice Hoses

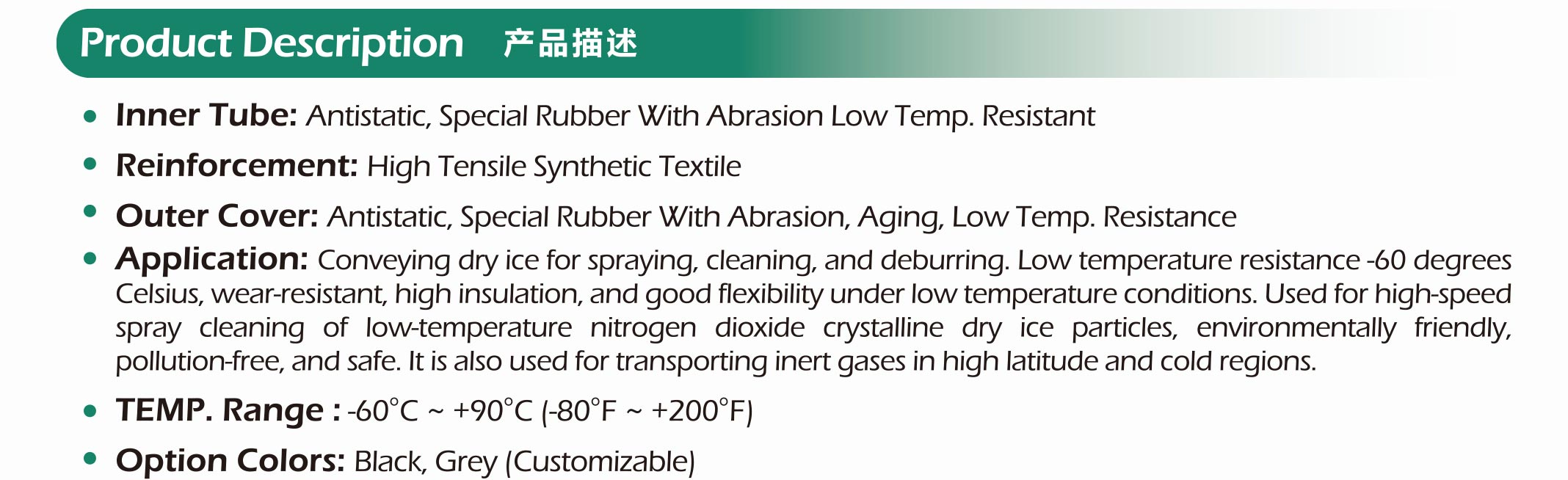

When choosing a dry ice hose, several key features must be considered. These hoses are designed to offer superior performance, durability, and safety. Let’s break down the essential characteristics:

1. Temperature Resistance

Dry ice hoses are designed to withstand extremely low temperatures, often as low as -60°C, ensuring the material remains intact and functional even in the harshest environments.

2. Pressure Tolerance

These hoses are built to handle the high pressure that can occur when transporting dry ice, ensuring that the gas flow remains constant and controlled.

3. Durability

Dry ice hoses are typically made from high-quality materials like reinforced rubber or specialized polymers that prevent cracking or wear, even after prolonged exposure to dry ice.

4. Flexibility

A crucial feature, flexibility ensures that dry ice hoses are easy to handle and maneuver in various industrial settings without compromising safety.

5. Safety Features

With dry ice’s potential hazards, such as suffocation risks from CO₂ gas and the extreme cold, safety features like reinforced walls, leak prevention, and non-slip outer layers are integrated into the design.

Applications of Dry Ice Hoses

Dry ice hoses are vital in multiple industries, serving unique and critical functions. Here are some of the primary applications:

1. Food Industry

Dry ice is commonly used to transport frozen goods and maintain the cold chain in food processing and packaging. The dry ice hose is used to inject CO₂ into cooling systems or for direct handling of dry ice during packaging.

2. Medical and Pharmaceutical Industries

In hospitals, laboratories, and pharmaceuticals, dry ice hoses play a crucial role in transporting and storing biological specimens, medicines, and vaccines that require extremely low temperatures to remain viable.

3. Cryogenics

Dry ice is often used for cryogenic freezing of materials in scientific research, medical procedures, and industrial applications. Dry ice hoses are essential in maintaining a consistent environment for these delicate processes.

4. Industrial Cleaning

Dry ice blasting is an environmentally friendly cleaning method where dry ice pellets are accelerated through a hose at high speeds to clean machinery, equipment, and surfaces without the need for chemicals or water.

5. Entertainment and Special Effects

In the entertainment industry, dry ice hoses are used to create fog effects for stage productions, concerts, and film shoots.

![]()

Choosing the Right Dry Ice Hose for Your Industry

Selecting the right dry ice hose can greatly impact the efficiency and safety of your operations. Here are some considerations to make when choosing a hose for your needs:

Material: Ensure the hose is made from materials that are capable of withstanding the cold temperatures and stresses associated with dry ice. Reinforced rubber or thermoplastic elastomers (TPE) are commonly used for their flexibility and durability.

Length and Diameter: Choose the hose length and diameter based on the specific requirements of your operation. Longer hoses are ideal for flexibility, while the diameter will depend on the volume of CO₂ that needs to be transferred.

Safety Standards: Ensure the hose complies with industry safety standards to avoid accidents or damage to equipment. Check for certifications such as ISO, CE, or UL.

Temperature Range: Verify the hose can handle the extreme low temperatures associated with dry ice, often well below freezing. This is especially critical in applications like cryogenics and pharmaceutical transportation.

Maintenance and Care for Dry Ice Hoses

Proper maintenance is essential to prolong the lifespan of dry ice hoses and ensure safe operation. Here are some tips for maintaining your dry ice hose:

1. Regular Inspection

Periodically inspect hoses for signs of wear, such as cracks, brittleness, or leaks, which can occur due to the extreme conditions in which they operate.

2. Cleaning

After use, ensure the hoses are properly cleaned. Use non-abrasive materials to wipe down the hose and ensure no dry ice remnants or contaminants remain inside.

3. Storage

Store hoses in a cool, dry environment away from direct sunlight and excessive heat to prevent degradation of the material.

4. Avoid Kinks and Twists

Ensure that hoses are not kinked or twisted when in use or stored. This helps to maintain their integrity and prevent damage over time.

The Future of Dry Ice Hose Technology

As industrial processes continue to evolve, so too does the technology behind dry ice hoses. Innovations in materials science, pressure regulation, and hose flexibility are paving the way for even more efficient, durable, and cost-effective solutions. The future promises hoses that are not only more robust but also safer and easier to handle, benefiting industries around the world.

Dry ice hoses are an integral component in a wide range of industries, ensuring that operations involving extreme cold or pressure are carried out safely and efficiently. From food processing to medical applications, the right dry ice hose can improve productivity, reduce downtime, and enhance safety. By understanding the features, applications, and maintenance practices associated with these hoses, businesses can make informed decisions about their cooling and refrigeration needs. With ongoing advancements in technology, the future of dry ice hoses looks promising, offering even greater reliability and performance.