The pharmaceutical industry will not compromise the precision, safety, or purity of its products. All manufacturing operations require the highest standards to guarantee the efficiency of drugs and related products. Out of a great number of segments that are deemed critically important to meet these standards, PTFE hoses are crucial for material transfer.

Antistatic PTFE hoses are globally acclaimed for their exceptional characteristics. They are ideally suited to meet pharmaceutical requirements mainly due to their low affinity for moisture, chemical resistance, and longer service life.

As one of the most reputed PTFE Hoses Manufacturers, Passion Hose products are specially developed to cater to the needs of the pharmaceutical industry in terms of quality, durability, and, most importantly, safety. In this blog, we understand the role of PTFE hoses in maintaining purity while transferring materials, their characteristics, and why it is so important to select the right manufacturing company.

Understanding PTFE Hoses

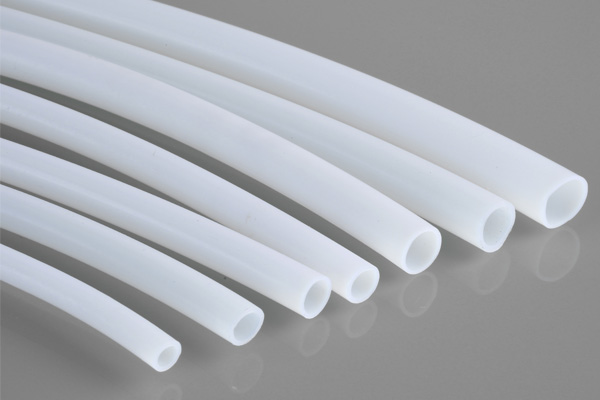

PTFE stands for (polytetrafluoroethylene) and is a fluorophore polymer that will not chemically react, has a chemically inert surface; and it can withstand high temperatures. PTFE hoses are made from this remarkable material yet the material being mostly flexible it can be covered with a stainless steel braid for increased working pressure. These hoses are universal in their application but some of the features make them very suitable for use in the pharmaceutical industry.

PTFE hoses are designed for the transfer of a wide range of products like liquids, gases as well as powders without having to compromise the material being transferred. This is mainly so in the pharmaceutical industry since contamination could effectively mean discarding everything, products included.

Why Do Pharmaceutical Businesses Need PTFE Hose?

1. Ensuring Material Purity

One of the most significant needs in the pharmaceutical industry is to ensure that the material, used or produced at any given time, is pure. PTFE hoses are non-stick, the surface of the hoses is smooth which helps to reduce any ability of material to stick to the surface of the hose.

This particular property positions them to suit the delivery of active pharmaceutical ingredients(APIs), solvents, and other labile substances.

2. Outstanding Chemical Resistant

Pharmaceutical manufacturing entails the utilization of a variety of chemicals, which in most cases, are acidic and strongly basic chemical substances that deposit large volumes of corrosive materials.

PTFE hoses have very good compatibility with a very wide range of chemicals from aggressive conditions such as acids and alkalis to organic solvents. The smooth bore hose also does not degrade over time, this counteracts any danger associated with contamination and health risks due to the use of a faulty hose.

3. High-Temperature Tolerance

Pharmaceutical manufacturing also requires temperature management most especially during sterilization and handling of raw materials or products. PTFE hoses can compare temperatures with ease ranging from - 65 degrees Celsius to + 260 degrees Celsius, these hoses can be useful in applications that require high temperatures or they can withstand ice-cold climates.

The fact that they can retain their structural characteristics under such conditions guarantees the former's performance credibility.

4. Compliance with Industry Standards

The sponsor must also ensure that they meet the required standards and certification of the industry in which the firm operates. Pharmaceutical PTFE hoses meet necessary requirements that include FDA and USP Class VI and are manufactured according to the EU directives.

It also explains why Passion Hose manufacturers pay attention to these certifications and aspire to produce products that are safe and of the highest achievable quality.

5. Flexibility and Durability

Even if these hoses possess strong chemical and physical properties, the PTFE hoses possess high flexibility which makes the hoses maneuver in restricted, cramped corridors and other arrangements typical in pharmaceutical firms. The steel reinforcement used in them is stainless to ensure that they can hold high pressures for a long time as well as endure regular use.

Uses of PTFE Hoses in Pharmaceuticals

PTFE hoses play a vital role in several pharmaceutical processes, including:

1. Movement of APIs

APIs are the molecular structure of drugs and their safe interchange is definitive. Because it is chemically inert, does not leach, and imparts no taste, PTFE hoses play crucial roles in ensuring the quality and inviolability of APIs in manufacturing and packaging.

2. Sterile Fluid Transfer

The PTFE hoses can safely transport fluids from one process to another where contamination is highly undesirable, for instance in manufacturing injectable drugs.

3. Solvent Handling

Solvents are widely employed in the manufacture of drugs in such activities as wiping and formulation. Due to these causes, PTFE hoses are recommended for use when dealing with the following chemicals because their surfaces do not react with any of these chemicals.

4. Powder Transfer

During the process of making tablets and capsules or any other solid dosage forms, the need to convey powders and granular materials without the possibility of losses or contamination is met by PTFE hoses.

5. Steam and Heat Transfer

The use of steam sterilization, in the course of production of pharmaceutical products, is widely observed. In our use of PTFE hoses for conveying high-temperature steam, we are assured of effective cleaning and sterilization of contaminating substances, at the same time we do not have to worry about the hoses degrading.

How to Choose the Right PTFE Hose

Selecting the right PTFE hose for pharmaceutical applications involves careful consideration of several factors:

● Material Compatibility

It should be established that the hose to be used should be made from a material that is compatible with the substances that are going to be used in conveying. Do not hesitate to talk to a PTFE Hoses Manufacturer about the most suitable product to be used for a particular application, Passion Hose for instance.

● Difference Temperature and Pressure Ratings

These regulations provide temperature and pressure limits for a boiler. It is also important for the hose to be able to handle the operating temperatures and pressures of your processes.

● Certification and Compliance

Select flexible hoses that are normally used in the industry and hoses that have industry certification-sanctions, better, if the hoses can be used in pharmaceutical sites.

● Customization Options

It was as a result found that customer requirements may vary from one pharmaceutical facility to another.. Select a manufacturer who offers a variety of the products that are manufactured such as length, diameter, and the sort of fitting.

● Quality Assurance

It must be purchased from a certified manufacturer such as Passion Hose that adheres to high standards and states of the art in its production of high-quality and high-performance hoses.

Why source for PTFE hoses from a reputable manufacturer

The amount of profit-making motives in PTFE hoses manufacturing either increases or affects the reliability and performance of the hoses depending on the manufacturer. These companies such as Passion Hose reveal the market experience which provides a guarantee to the products along with security. By choosing a trusted PTFE Hoses Manufacturer, pharmaceutical companies gain access to:

Expert Guidance: Manufacturers are always in the best position to provide recommendations on the type of hose to use, how to install them, and how to maintain them.

Wide Product Range: This company names its product Passion Hose and claims to have a variety of PTFE hoses to be used for particular operations.

Commitment to Innovation: Manufacturers will always aim at releasing products that would satisfy the various needs as can be seen from the present manufacturing sector.

Uncompromising Quality: Exhaustive testing assures that all hoses perform efficiently as will be seen under the prevailing circumstances.

The Best Ways to Keep PTFE Hoses Long-Lasting and Effective

To maximize the lifespan and efficiency of PTFE hoses in pharmaceutical applications, consider the following maintenance tips:

● Regular Inspection: Check the hoses for any signs of rapture, change in color or distortion.

● Proper Cleaning: Hoses should be cleaned after use to avoid encouraging the buildup of the different materials one after the other.

● Avoid Overbending: Apply adequate fittings and support to relieve the load at the hose.

● Replace When Necessary: The best hoses though are not immortal and therefore they are bound to wear out at some one point in time. Replace them as the manufacturer has suggested they should be replaced.

Conclusion

Pharmaceutical industries cannot afford to do without PTFE hoses, which play the role of conveying matters of a pharmaceutical nature while maintaining their original quality and safety. Owing to their chemical and heat resistance, as well as compliance with industrial specifications these bearings are relied upon to perform high-level functions.

Passion Hose is among the most outstanding PTFE Hoses Manufacturers, and our PTFE Hoses are characterized by quality, reliability, and innovation. With the right PTFE hose, PTFE hose selection, and proper hose maintenance, pharma organizations can guarantee safer production and better product quality.

Discover Passion Hose's Line of PTFE Hose

Do you need the best PTFE hose for your pharmaceutical applications? Check the wide array of Passion Hose's Superior Hoses by clicking on the products tab. To this end, commitment to quality is observed strictly, in order to meet the peculiar needs of the pharmaceutical producers. Call us now and begin the journey to uncompromised purity and performance.