The Importance of PTFE Hose in Food and Beverage Processing

Product quality, safety, and supply chain efficiency will be affected as the particulars of your production equipment come to bear, based on food and beverage regulatory and quality demands. Likely the award for uniqueness and compatibility should go to PTFE Hoses right here. In particular, hexafluoropropylene polymer (PTFE) hoses have been utilized as a piece of sustenance and devour preparation.

We will speak about why PTFE jobs made their affiliate your singular accomplishment in this area. An expert in the manufacture of tailored PTFE hoses, Passion Hose below outlines the advantages and uses (in detail) with top features to attain premium food safety standards.

So therefore (and I hope the odd industrial food producer or micro-beverage producer who does things right and disinfects his/her ingredient sees this), PTFE hoses CAN be happy, but it is the awareness of how they operate in regards to your whole system. So, let's cut to the chase with this hotbed of an issue.

Demystifying PTFE Hoses for Food and Beverage Processing

This nonreactive, nontoxic characteristic at high temperatures is synonymous with PTFE hoses. All these key specifications make them ideal for applications demanding top-notch hygiene, durability, etc.

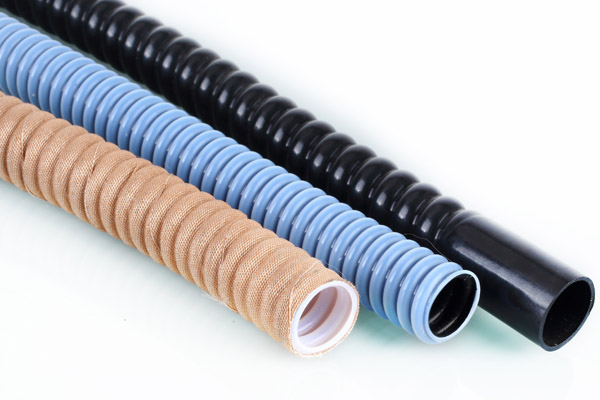

These styles are very common in PTFE hoses for the food and beverage industry requiring an external layer of braided stainless steel either to enhance durability or strength without detriment to flexibility. For example: Passion Hose manufactures extra careful manufacturer PTFE hoses used in a food and beverage atmosphere.

Why PTFE Hoses Are Essential

● Non-Reactive and Safe

PTFE is very unreactive with food or beverage products. Which can actually stop liquids (like potable food) from being yucky. Take, for example, PTFE hoses that are regularly applied to deliver acidic, alkaline, or alcohol-based fluids without affecting their properties whatsoever.

● Resistance to High Pressure and Temperature

In food and beverage processing, there are almost always outright extremes — you either sterilize or produce under high heat. They can also withstand high heat and will not deteriorate, making them ideal for HOT oil transfer or transferring hot/steamed liquids (PTFE hoses).

● Hygienic and Easy to Clean

One of the main advantages of PTFE hoses is their nature since the non-stick and silky surface doesn't allow for bacteria, food debris, or residue to stick. Such properties render them easy to clean whilst following the hygiene standards set by the authorities.

● Durability and Longevity

PTFE hoses (especially those stainless steel braided) are durable and consequently more resistant than regular hoses. Do not need to replace as frequently so there is less downtime from production lines.

● Versatility

PTFE hoses are for various applications such as delicate beverages and wine to viscous or particulate-rich material like syrups and sauces. They are a catch-all solution across the food and beverage spectrum that provides versatility for manufacturers.

Applications of PTFE Hoses in the Food and Beverage Industry

1. Beverage Production

PTFE hoses are the ideal choice for transferring drinks like juice, soft drinks, and(white and red) wine, and beer. They are non-reactive, thus ensuring that the flavor and nature of these products do not change with processing.

2. Dairy Processing

Milk, cream, yogurt along with other dairy treats manufactured from dairy need to be transported using PTFE hoses. Ultra-smooth surface, which hinders bacterial growth and allows for stringent maximum hygiene demands to be met.

3. Oil and Fat Transfer

It — is pumping high-temperature oils and fats. That is the perfect application for PTFE hoses, they can endure high temperatures making them a great component for this.

4. Confectionery Manufacturing

Sticky or extended, high-temperature objects are often thought to be in candy and cocoa items. The non-stick properties of PTFE hoses help in transferring these ingredients without clogging up.

5. Canning and Bottling

Used in those automated product canning/bottling line systems, the flexibility and durability of PTFE hoses are ideal for uninterrupted operation.

Choosing the Right PTFE Hose

How to Choose PTFE Hose for Food and Beverage Applications Below are a few tips to help you out:

Know the Requirements of the Application: Take into account what material will be transferred; temp ranges, and pressure conditions. As an example, pumping acidic juices will need a hose with high chemical resistance.

Meet Quality Standards: Make sure you choose hoses only from some of the well-known manufacturers of PTFE hoses like Passion Hose who comply with various industry standards. A quality hose carries Quality assurance, hence food-safe features can be expected.

Choose the Right Specs: Always make sure that the hose diameter, length, and pressure rating are appropriate for your system. So that you do not waste and you do not get stuck in reaction to the security in the production processes.

Look For Durability Features: If you have hot or abrasive applications, select braided stainless steel reinforced PTFE lines.

Ptfe Hoses — Maintenance And Care

This is some maintenance done to get the most out of those lovely PTFE hoses you have:

● Routine Inspection: Condition and Damage Check (especially around fittings).

● Cleaning Appropriately: Clean with the right disinfectants for hygienic contents while ensuring cleanliness and no harm is done to the hose.

● No Over-Bending: PTFE hoses are designed to have a few bends here and there but excessive bending in the same place can result in a short lifespan.

● Proper Storage: Leaving hoses in excess heat or direct sunlight, or even leaving your coil hose on the ground will cause damage to it over time so when you are not using them take better care of them.

The Role of PTFE Hoses Manufacturers

PTFE hoses for food and beverage processing must be high quality, and only investment manufacturers like Passion Hose have the ability to add value. These are put through strict tests and industry standards to allow their products to perform in extreme conditions.

But you can opt for any of the trusted PTFE hose manufacturers for your needs and be assured of unparalleled strength, performance, and reliability. Along with massive hose inventories, these manufacturers provide you with information for selecting hoses, in turn providing the right product for your application.

Conclusion

And with high safety standards, durability, and maximum efficiency PTFE hoses take a very important place in food and beverage processing. Whether moving temperature-sensitive beverages or transporting hot oil, they are a kind of building block of modern food production systems due to their versatility.

With proper knowledge of PTFE hose properties & good practices at your end, while selecting a PTFE hose, you can bank upon top-quality products manufactured by brands like Passion Hose that keep quality and safety as their top standards.

PTFE Hose Training Collection by Potential Passion Hose

Eager to improve your food and beverage processing systems? Explore the PTFE Hose Range of Passion Hose and Find The Right One. Even if the scare gets to you and you want to switch gears a little, trust this best amongst the best PTFE hose manufacturers ahead of each wave crossing your way.

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China