In the injection molding industry, stability, precision, and reliability of every machine component are essential to achieving consistent product quality and maximizing production efficiency. PTFE (Polytetrafluoroethylene) tubing has become a preferred choice for injection molding equipment thanks to its outstanding thermal stability, chemical resistance, and long service life. As a professional manufacturer and exporter of PTFE hoses, we provide high-performance solutions designed to support the demanding conditions of modern injection molding processes.

1. Why PTFE Tubing Is Ideal for Injection Molding Machines

Injection molding machines operate under high temperatures, pressure changes, and exposure to various hydraulic oils, coolants, and chemical additives. PTFE tubing offers unique advantages that traditional rubber or metal hoses cannot match.

• Exceptional High-Temperature Resistance

PTFE can withstand continuous working temperatures up to 260°C (500°F), making it ideal for the heating zones and high-thermal environments commonly found in injection molding operations.

• Superior Chemical Resistance

Hydraulic oils, coolant fluids, plastic additives, and cleaning chemicals do not degrade PTFE. Its non-reactive nature ensures long-term durability and prevents corrosion or chemical wear.

• Ultra-Smooth Inner Surface

The smooth bore design minimizes flow resistance and prevents blockage, contributing to stable hydraulic or coolant flow and improving machine efficiency.

• Non-Stick and Anti-Contamination Properties

Molten plastic particles and impurities do not adhere to PTFE’s surface, keeping the tubing clean and reducing maintenance downtime.

• Excellent Pressure Stability

-Reinforced PTFE tubing can handle high-pressure hydraulic conditions without deformation, ensuring safe and reliable machine performance over long production cycles.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

2. Typical Applications in Injection Molding Equipment

PTFE tubing is widely used in various sections of injection molding machines, including:

-Hydraulic oil transmission lines

-Cooling and temperature control circuits

-Chemical supply lines

-Air and vacuum channels

-Mold temperature control systems

-Lubrication fluid pathways

Its versatility makes PTFE a critical component for both standard injection molding machines and high-performance precision molding equipment.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

3. Benefits for Injection Molding Manufacturers and Operators

Using PTFE tubing brings several long-term advantages:

• Improved Machine Reliability

Reduced leakage, higher thermal endurance, and better chemical protection extend the overall system lifespan.

• Lower Maintenance Costs

The non-stick and corrosion-resistant properties significantly decrease cleaning time and replacement frequency.

• Higher Precision in Molded Products

Stable fluid transfer ensures consistent operating conditions, resulting in tighter tolerances and better-quality finished parts.

• Enhanced Safety

PTFE retains mechanical strength under extreme conditions, reducing the risk of hose failures or unexpected machine shutdowns.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

4. Custom PTFE Tubing Options for Injection Molding

To meet the diverse requirements of different machine brands and global markets, we offer customizable solutions:

-Inner diameter (ID) and outer diameter (OD) customization

-Smooth bore or convoluted types

-High-pressure stainless steel or Kevlar reinforcement

-Anti-static PTFE options

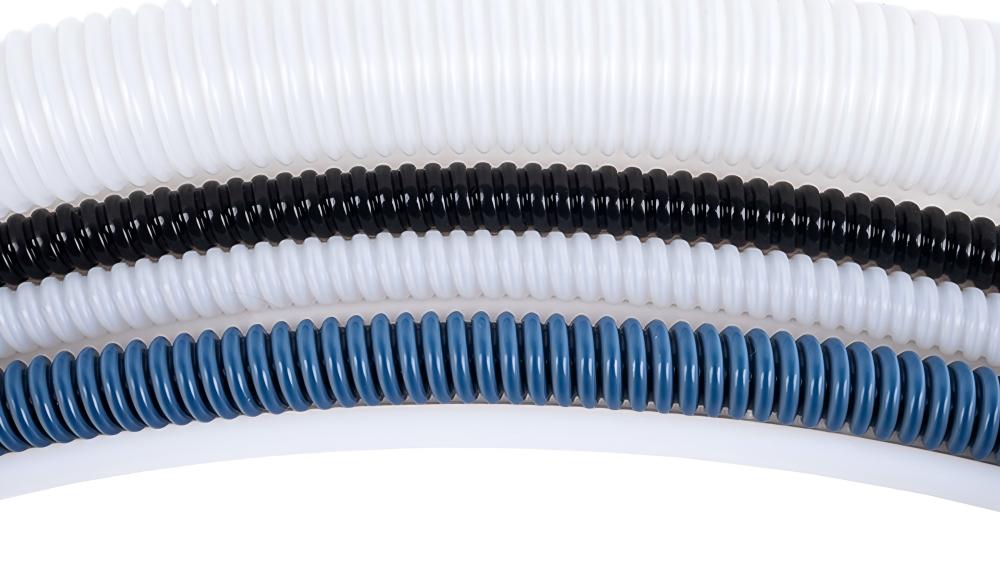

-Various colors for identification and routing

-Pre-assembled fittings and connectors

Our products undergo strict quality inspection to ensure consistent performance in demanding industrial environments.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

5. Why Choose Us

As a dedicated manufacturer and exporter of PTFE hoses and fluoropolymer tubing, we provide:

-Professional engineering support

-Stable quality and competitive pricing

-Fast delivery for global customers

-Industry-specific solutions for injection molding, automation, chemical processing, and fluid handling

Our goal is to help injection molding factories improve efficiency, reduce downtime, and maintain high-quality production stability.

PTFE tubing has become an essential component in modern injection molding machines due to its unmatched thermal stability, chemical resistance, and reliability. Whether you are upgrading equipment, enhancing machine performance, or designing new machinery, PTFE hoses offer a long-lasting and cost-effective solution.

If you need customized PTFE tubes for injection molding applications, feel free to contact us for technical support and product recommendations.

Janet Yao

WhatsApp: +86-13666632043

Email: ps005@parshun.com