PTFE Hoses in the Chemical Industry: Ensuring Safety and Reliability

Chemical processing is one of the most challenging industries to operate in, and making sure that your equipment has the highest level of reliability and safety is a number one priority. Among the various tools that are integral to these operations, one of them is PTFE hoses (polytetrafluoroethylene), which come with premium quality and corrosion-resistant properties. These are employed in services that necessitate safely conveying extreme fluids, high-heat items, and corrosive agents.

Passion Hose is a reputed specialty PTFE hose manufacturer and offers a premium range of quality PTFE hoses that can withstand heavy-duty service in the chemical industry. Their line of products, which ranges from the ground to end-of-line systems, are made for demanding applications to withstand harsh environments and provide operation reliability and safety.

In this blog, you can find out what makes PTFE hoses crucial for chemical applications along with their advantages, guidelines to pick the best one & some maintenance tips on how you can make its life longer. It helps if you are a chemical engineer, plant manager, or operator to choose the right PTFE hoses for your chemical processes after reading this guide.

PTFE Hoses: PTFE in the Chemical Sector

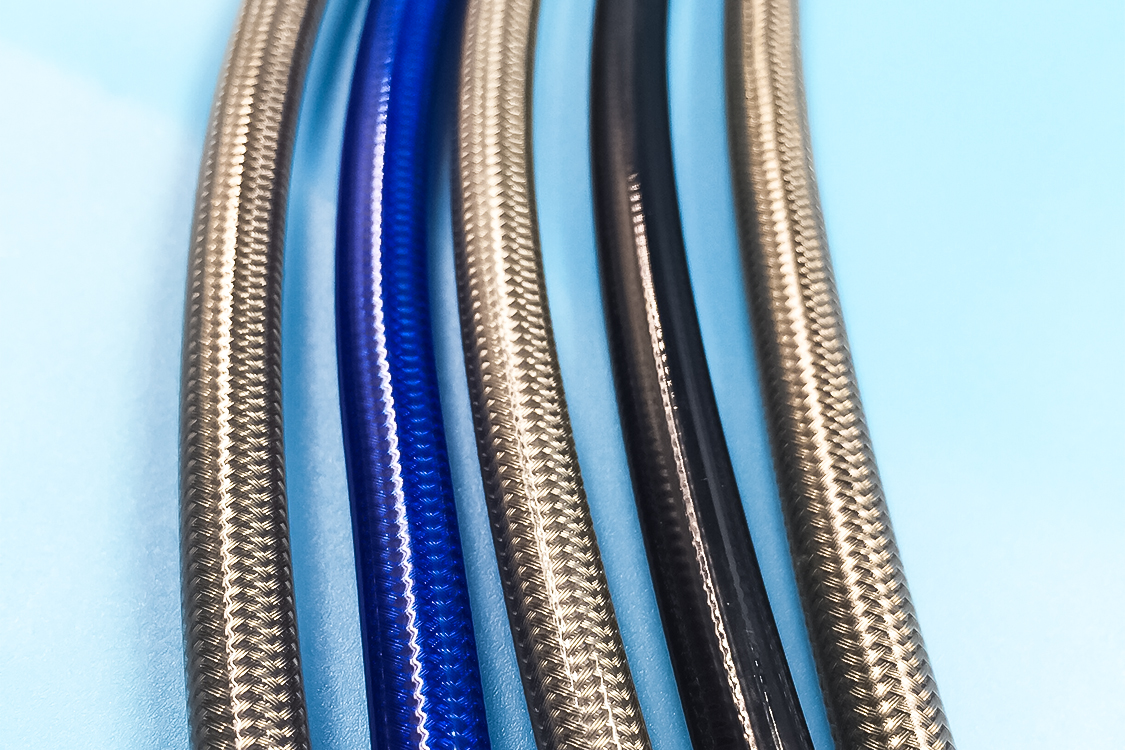

A PTFE (Polytetrafluoroethylene) hose is a high-performance synthetic polymer that is renowned for its non-reactive durability. Often the hoses are reinforced with (usually stainless steel) braiding adding mechanical strength and flexibility.

Applications for PTFE Hoses (And Why It Is the Best Choice)

● Chemical Resistance: PTFE hoses are resistant to nearly all chemicals, including acids, bases, solvents, and oxidizing agents with little chance of degradation.

● Operating Temperature: They can work across a wide temperature range; working in extreme cold or at high heat, which makes them ideal for diverse chemical processes.

● No Wettable Surface: The low friction, non-stick interior removes the contact that may leave residue from laying down keeping a steady flow and preventing contamination.

● Resilience: Great wear resistance and don't change even under pressure.

And this is precisely why chemical manufacturers are favored with PTFE hoses when it comes to the transfer of fluids in a reliable and safe manner.

PTFE Hoses In The Chemical Industry

PTFE hoses play a crucial role in several chemical industry activities, such as:

Corrosive Acid & Solvent Transfer: Move corrosive acids and solvents, with NO degradation risk to the hose.

Mechanical Structures for High Temperatures: Operating at high temperatures helps processes like chemical distillation and reaction.

Transporting & Storing Chemicals: Loading & Unloading Chemicals.

Pharma and Finer Chemicals: Providing contamination-free high-purity fluid transfer of chemicals.

Gas and Vapor Transfer: For transporting aggressive gases, in a chemical production process or laboratory.

They are very versatile and used in a wide range of short-term industrial facilities as well as many types of chemical laboratories.

Benefits of Using PTFE Hoses

Ultimately, it is the PTFE Hoses that ensure these high standards of safety and efficiency are met within the chemical industry.

● Superior Safety

The other hazardous threat, of course, is the chemical spill and leak. Since PTFE hoses are non-porous and chemical resistant, they help to minimize the chances of these leaks which not only hold the potential for environmental disasters but also harm employees.

● Enhanced Reliability

PTFE Hoses with their robust build, continue to perform well even during extreme conditions and thus lead to lesser equipment failure downtimes.

● Longevity

PTFE material is even more durable, which means a longer life; in this case, paying less to operate over time.

● Versatility

To cover all chemical usage and operating conditions with another type of hose is not possible without the need for an enormous number of different types of cord, created to be only specific to a certain application; hence why Elastomeric Cord takes several years.

How to Choose PTFE Hose for Chemical Service

Choosing the Right PTFE Hose is also a major factor for conducting chemical activities safely and efficiently. Now do bear this in mind while making your choice:

Chemical materials: Each chemical has a compound provided to it. Look at the manufacturer's compatibility chart to see if it is resistant to the chemicals you will be using.

Temperature & Pressure Ratings: It also covers temperature and pressure ratings: For example, while considering the temperature extremes and pressure levels, choose a hose that has a target value at least equal to or more than expected conditions.

Diameter and Length of Hose: Pick the appropriate girth and size based on your flow speed and installation.

Braiding Material: Select braiding material based on your need i.e. strength and flexibility. Mercedes-Benz Engineering has also said they usually opt for stainless steel braiding because it holds up better in brutal conditions.

Quality Certification: Choose hoses from reputed companies like Passion Hose which offers high-quality hoses according to industrial standards.

Cleaning and Maintenance of PTFE Hoses

To fulfill the full potential of PTFE hoses in chemical applications you need to understand their material maintenance. Follow these best practices:

● Regular Inspection

Hoses require regular inspection for wear, kinking, and damage replace any hoses that have been compromised to avoid system failures.

● Cleanliness

After each use, make sure sinks or hoses are washed to avoid chemical residues that will either weaken havoc on the hose in time or leak to function.

● Proper Storage

Avoid exposing PTFE hoses to sunlight as well as corrosive chemicals to avoid damage. Keep in a dry, sanitary location.

● Avoid Overbending

To minimize potential weakness within the hose during operation it should not be excessively bent and kinked, ensure proper fittings & supports/uploads.

● Stick to What the Manufacturer Tells You

The manufacturer has installation, use, and maintenance instructions; so read them and follow them to ensure your hose lasts as long as it can.

Advantages of Fitting PTFE Hoses from Passion Hose

Passion Hose is the Leading Manufacturing PTFE hose Manufacturer making its mark for quality and reliability for chemical application. Their PTFE hose range is:

● Built with high-quality materials for maximum durability.

● Approved and tested to really strict safety standards by the industry.

● Expert guidance in choosing the right hose for your specific usage.

Passion Hose is a selection for the guarantee of product safety and performance.

Conclusion

PTFE hoses are used in the chemical industry to provide unmatched safety, reliability, and performance. When it comes to transferring corrosive acids, high-temperature fluids, or requiring a guaranteed clean line feed, you won't find a better hose to do the job.

With knowledge of their function, how to choose appropriate specifications and proper maintenance guidelines, you will be able to use PTFE hoses safely for years. When it comes to quality, Passion Hose, one of the PTFE hose manufacturers, will provide you with high-standard products.

Passion Hose PTFE Hose Series

Should you be interested in implementing our trustworthy high-grade PTFE hoses in your chemical processes? Head towards the PTFE Hose Collection by Passion Hose and explore the best suitable for you.

Passion Hose: When You Need To Get It Right Passion Hose provides quality and safety solutions for all operations. It was founded by dedicated people who believe that quality and safety should never be compromised in operations.

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China