What is a Welding Hose? Key Features and Applications

Industrial machines need high-quality connectors to maintain continuous, uninterrupted operations. The welding hose functions as an essential gas delivery system in metalworking operations to establish secure paths for combustible gases and oxygen between all welding, cutting, and brazing processes. Welding operations exist in extreme conditions that require components that perform well and protect against damage. The advanced silicone vacuum hose manufacturer Passion Hose provides welding hoses according to industrial-grade requirements. This paper examines welding hoses by explaining their definition, main specifications, and wide range of industrial usage.

Why Are Welding Hoses Important in Industrial Equipment?

Multiple fabrication and metal processing gas-powered tools require welding hoses as their fundamental operation component. Pressure-resistant flexible hoses need to transport combustible gases safely without wearing them out. The designed structure of welding hoses enables the safe distribution of gases, including acetylene, oxygen, propane, and various others, without allowing leakage or chemical destruction. The material reliability of welding hoses remains essential because they are regularly used in high-temperature, abrasive, and mechanically challenging environments.

Key Features of Welding Hoses

Dual-Line and Single-Line Configurations

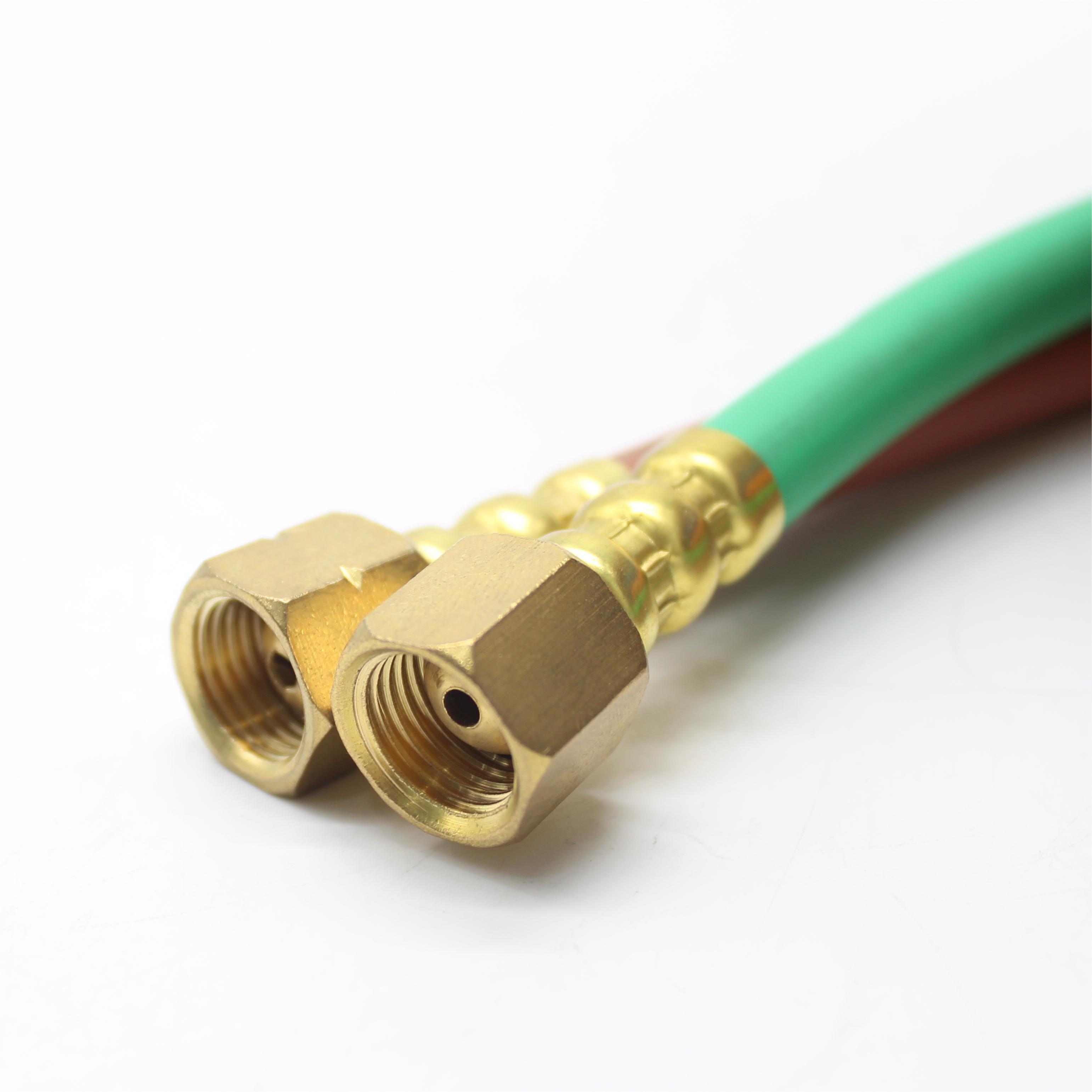

Welding hoses are released to the market in dual-line and single-line designs. The supply of fuel and oxygen through dual-line hoses receives color-coded identification as red stands for fuel gas and blue represents oxygen. The dual channels organize hoses while limiting entanglement to maximize work process efficiency. Lightweight single-line hoses best suit scenarios requiring a single gas tubing configuration.

Durable Outer Cover

A welding hose needs outer materials that combat exposure to abrasion alongside oil hea,t, and fire in addition to abrasion. Manufacturers select high-grade synthetic rubber together with thermoplastic materials for their manufacturing needs. External damage to the inner tubing can be prevented by installing these protective materials, which also increase the hose's longevity. As a silicone vacuum hose manufacturer, along with its welding hoses range, Passion Hose maintains quality control standards for product durability across every product line.

Inner Tube Compatibility

The tube inside the hose must suit whatever gases the user plans to work with. Special measures focus on testing oxygen and acetylene hose inner linings for their ability to stop permeation and gas leaks. The quality of hoses determines both safety measures and excellent welding functions.

Pressure Resistance

Working pressures of welding hoses fall under a specific range, which spans from 200 PSI to 300 PSI according to their intended usage. High-demand operation conditions are supported through braiding reinforcement and internal construction elements that sustain pressure requirements.

Flexibility and Handling

Industrial welding hoses must maintain enough flexibility to allow operators unrestricted movement while performing welding jobs. A hose that becomes rigid or prone to kinking might produce uncontrolled torch functions and dangerous gas interruptions. The silicone vacuum hose manufacturer Passion Hose implements flexible designs from their recognized experience in the industry to produce welding hoses that boost performance and safety for workers.

Typical Applications of Welding Hoses in Industrial Settings

Metal Fabrication Shops

Welding hoses represent a fundamental piece of equipment that maintains operations in metalworking facilities that continuously execute cutting welding and brazing procedures. Gas cylinders link through pipes to torches to deliver continuous fuel and oxygen streams for precision applications.

Construction and Infrastructure

The survival of welding hoses in construction sites depends on their ability to endure harsh environments during framework and pipeline welding operations. These hoses should work adequately even during movements across concrete surfaces while exposed to UV light and highly variable temperatures. The welding hoses from Passion Hose support all industry performance criteria, and the company continues to be recognized as a leader in silicone vacuum hose manufacturing and supply.

Automotive and Aerospace Industries

Automotive garages and aerospace industries rely on durable welding hoses for metal panel bonding, chassis repairs, and structural fabrication work. Using aluminum or titanium metals in these industries requires precise gas mixtures and a stable hose system.

Shipbuilding and Marine Applications

The marine sector employs welding hoses to perform essential heavy-duty jobs, which include ship hull restorations, onboard ship structural welding, and pipeline setup operations. Tasks that require these hoses occur in conditions marked by exposure to water damage, salt accumulation, and intense machinery abrasion.

Manufacturing and Industrial Maintenance

Welding hoses are essential equipment that powers manufacturing facilities that perform periodic equipment maintenance and fabrication and pipeline repair tasks. High-volume production areas require reliable hoses because their operational dependability directly affects production stoppages and workplace safety.

How to Choose the Right Welding Hose for Your Needs

Identify the Required Hose Type

Depending on your welding process, the selected configuration must be either single-line or dual-line. Oxy-fuel tasks require the use of a dual-line hose for optimal performance. The single-line gas delivery system will typically meet the requirements when welding procedures using a single gas.

Check Gas Compatibility

Pick a hose that matches the gas form used: propane, oxygen, and acetylene. Different hose types mismatched for usage result in hazardous chemical reactions, and hose deterioration happens.

Evaluate Length, Diameter, and Flexibility

You will find welding hoses with inner diameters between ¼ and ⅜ inch and lengths spanning 25 to 100 feet. Select the hydraulic tubing that suits your work area's attainable length and maneuverability.

Review Compliance Standards

You should only select hoses approved by industrial standards. Safety, tolerance, and chemical resistance compatibility requirements are met when using hoses from manufacturers.

Maintenance Tips to Maximize Hose Lifespan

● Routine Inspection: A regular inspection involves looking for any damage to the hose through cuts and cracks while examining soft areas or blister formation.

● Proper Storage: The suitable storage location is a cool, dry area that should be kept away from sunlight, flames, and corrosive materials.

● Avoid Kinks: Tight coilages and twisted hoses will cause structural breakdown and obstruct natural gas flow through the system.

● Leak Testing: Detecting hose leaks requires using a mixture of soapy water at all connection areas and the hose's entire length. Never use a flame.

● Clean Couplings: The torch and regulator ends must remain clean while adequately fitted to prevent leaks and pressure drops.

The same fundamental maintenance procedures used for silicone hoses apply similarly to welding hoses as they extend both safe operation and operational performance.

The production experience at Passion Hose as a silicone vacuum hose manufacturer enables the company to develop welding hoses that require minimal maintenance and offer an extended operational life cycle.

Conclusion

Various industries need welding hoses because they deliver essential support during operations requiring safety, flexibility, and durable performance in demanding conditions. These hoses enable efficient welding operations and safe completion of important work in shipyards and automobile factories. Long-term operational success becomes possible when businesses select appropriate hoses according to their application, gas type, and compliance needs. As a well-known silicone vacuum hose manufacturer, Passion Hose maintains continuous innovation throughout all its hose categories.

Get Premium Welding Hoses and Silicone Hose Solutions from Passion Hose

The company provides peak-quality welding and premium silicone vacuum hoses that meet all requirements. Since inception as a silicone vacuum hose manufacturer, we have manufactured products compatible with demanding standards of metal fabrication, chemical processing, and high-performance industrial environments. Passion Hose provides customized industrial hoses, which you can learn about by contacting our team.

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China