Understanding the Importance of Welding Hose Fittings and Connectors

Hoses play only one role in the setup when welding. Fittings and connectors form the main link between systems. Many drivers forget about them, but they play a key part in protection and good driving. Fittings are necessary to join the Hose with the torch, regulator or tank for gas. Should they fail, every other system piece is put at risk. A good weld depends on having a secure space that does not leak.

This article by tells you why your choice of fittings and connectors is important, helps you find the right ones and shows you what you can rely on from a credible Welding Hoses Manufacturer.

What Makes Fittings and Connectors Important for Welding?

The gases used in welding, such as oxygen, acetylene, propane and MAPP, are sometimes carried by welding hoses. But the fittings help gas flow properly from where it starts to where it's used. Trouble will arise later on if you install ill-fitting or low-quality fittings. If the wrong parts are included, the equipment may cause gas leaks, unstable flames or risk explosions. For this reason, experts ensure that fittings are designed for the correct type of gas and a suitable hose. Your chosen Welding Hoses Supplier will show you the way when you need it. They know which gas and hose connectors are appropriate for which use.

Most Common Welding Hose Fittings

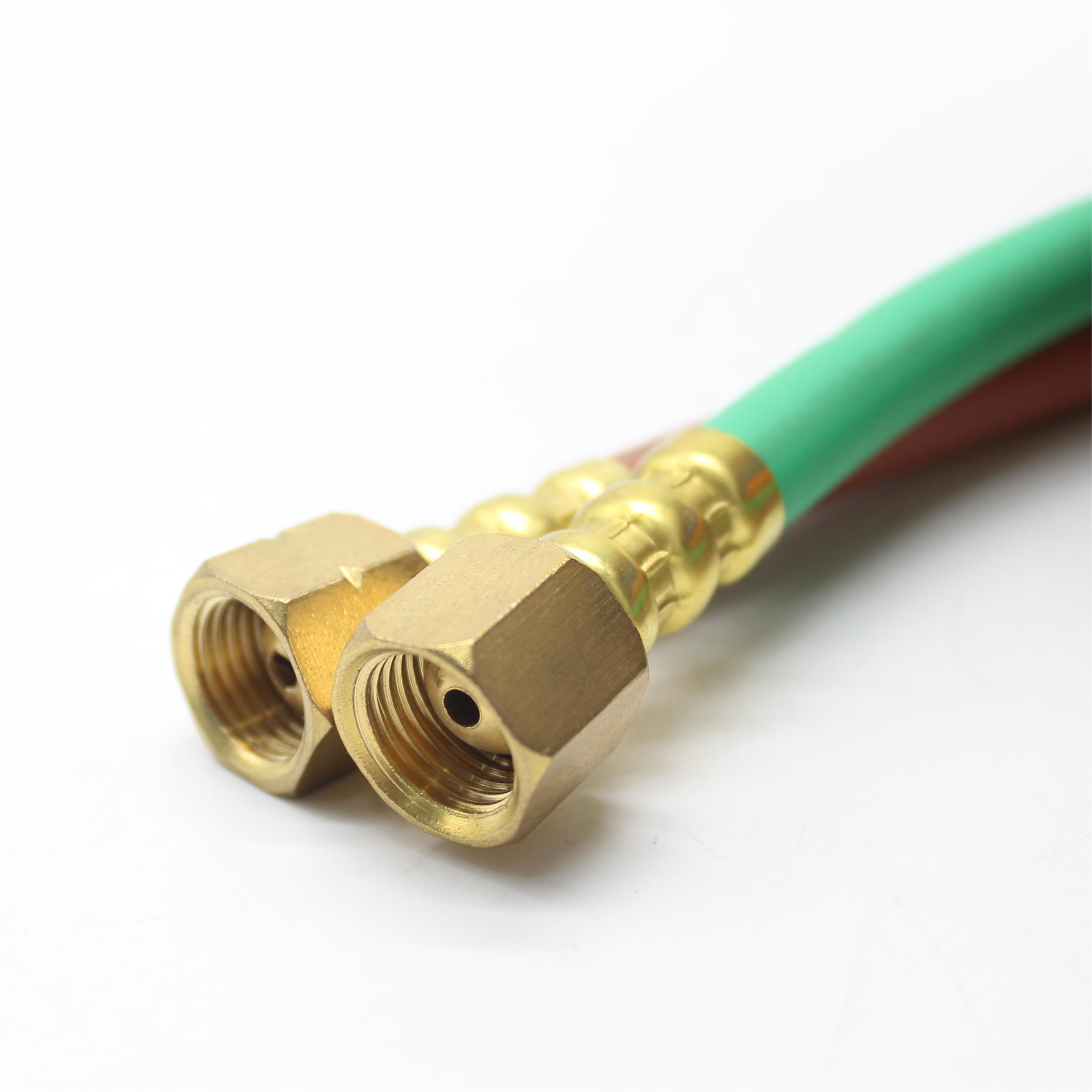

Many hose fittings exist; every type fits a special task and environment. For basic system designs, oxygen or acetylene is transported in single-hose fixtures. They're basic, dependable and found in many garages and auto shops. Advanced twin-hose fittings are now available. They are built for systems that need two hoses, one for fuel gas and one for oxygen. These are common in construction settings, manufacturing operations and big welding jobs. Quick-connect fittings are also available. With these tools, you do not need any tools to connect or disconnect hoses. You'll use these memory cards when access speed is essential. Changing hoses is fast and done without needing to stop the whole system.

What a home is built from is another aspect to consider. Most often, fittings use brass or stainless steel. You will usually find brass in indoor settings. A stainless jacket is best when the area is rough, filled with oil, solvents or exposed to the elements.

What Hose Grade Should You Use and What Connectors Fit?

No hose types — R, RM and T — are treated the same. R-grade hoses are designed for acetylene use but shouldn't be used with oil or propane. Most of their fittings are plain and designed for inside use. Even though they are sturdier, RM-grade hoses are still designed to be used with acetylene. Even though these fittings look much like R-grade, they usually have more durability to suit everyday use.

T-grade hoses can be used for a variety of things. They care for propane, MAPP gas, butane, and similar materials. Metalworkers need equipment that won't deteriorate or ignite when they use it in oily, dirty and outdoor environments. Every connector should be made from stainless steel or be specially coated. Damaging your entire system can happen if you use the wrong connector on a T-grade hose or any hose. Check with the manufacturer or supplier before getting or combining replacements for your Welding Hoses.

Fitting Your Equipment Right Makes Welding Safer

A lot of hazards are found at the connection points in gas welding. That's why we should check that the fittings are put on correctly and fit the Hose properly. Pressure rating must also be the same. When the pressure on your Hose is high but the fitting can't hold up, the connector will likely fail first. As a result, you may suddenly have a hose burst or leak. It's important to consider what types of thread are used as well. The type of threading used on some fittings depends on where the Hose was made or used. Wrong threading can result in either damage to the connector or holes where gas may escape.

During times like these, it becomes clear why you should choose a reliable Welding hose manufacturer. You'll get accurate and safe parts when you buy from us.

Determining When It Is Time to Replace Fittings and Connectors

Wear and tear happen to fittings, as they do to hoses. Repeated wearing away of threads and seals results from time, pressure and making new connections. The main thing is to recognise problems at the beginning. The fitting should be changed if there are cracks, rust or thread loss. Should you detect gas or loud hissing at the joint, immediately check the joint to see what's wrong. Sometimes it's not possible to see the development. If the torch acts unpredictably or loses pressure, check the fitting for the cause. Over the years, the inside of high-quality fittings can rust or become clogged.

It is best not to repair broken fittings with tape or sealants. They provide only temporary solutions and stop working in time. It's better to ask your Welding Hoses Manufacturer, Passion Hose, for the replacement parts.

Instructions on the Right Way to Install and Use

Before installing connectors, ensure the hose ends aren't soiled. A seal is not closed correctly when dirt or oil surrounds the joint. Connect the hose at the fitting and fasten it with the proper clamp or ferrule. Avoid over-tightening. Despite the impression of better safety, too much tightening can damage the fitting or twist its threads. Force the seal on your container tight, but not so hard as to break it. Don't keep unused connectors in damp or dirty areas. When something becomes wet, it can start to rust. The passage of air through the air conditioner can become clogged with dust.

Gas must be able to move freely, so these valves should be set up anywhere the direction of the gas flow can switch.

Picking a Credible and Trusted Supplier

The source for your fittings should be just as crucial as the fittings themselves. Outstanding Welding Hoses Manufacturers and Suppliers will provide:

● Gas-specific connectors

● Connection compatibility charts for hoses

● Pressure ratings that have been checked

● Certificates showing what the material is made of

● After-sales support

Trendy clothes are not the only thing you should pick. You should make certain by testing and checking the specifications. As a result, your system will hold up against effects from changes in pressure.

Trusted Welding Hoses Manufacturer: Passion Hose provides fittings with their hose products. You're offered the attaching fittings and safety gear for all hoses, which are included or suggested.

Conclusion

Although fittings and connectors are small, they significantly affect both your safety and how efficient your welding setup is. Picking the wrong adapter may cause gas leaks, increase the chance of a fire or result in poor performance. Choose the proper size fitting for your hose grade. Ensure all three—threading, pressure rating and material type—are right for your needs at work. Contact a genuine Welding Hoses Supplier who knows industry requirements when things are unclear.

Do you need suggestions for your welding fittings? Passion Hose sells tools and accessories for fittings, connectors, hoses and all your equipment needs. Pick a supplier who understands what you want.

Want to find out more about the correct welding hose fittings?

No matter if you're upgrading or starting a new project, you must use proper fittings. Passion Hose delivers top-quality hose assemblies and connectors suitable for every kind of gas and application.

Never use parts that aren't designed for your machine. Passion Hose can help you decide on the right fittings and provide a unique quote if you get in touch today.

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China