Understanding the Flexibility of Silicone Vacuum Hoses: Key Advantages for Complex Systems

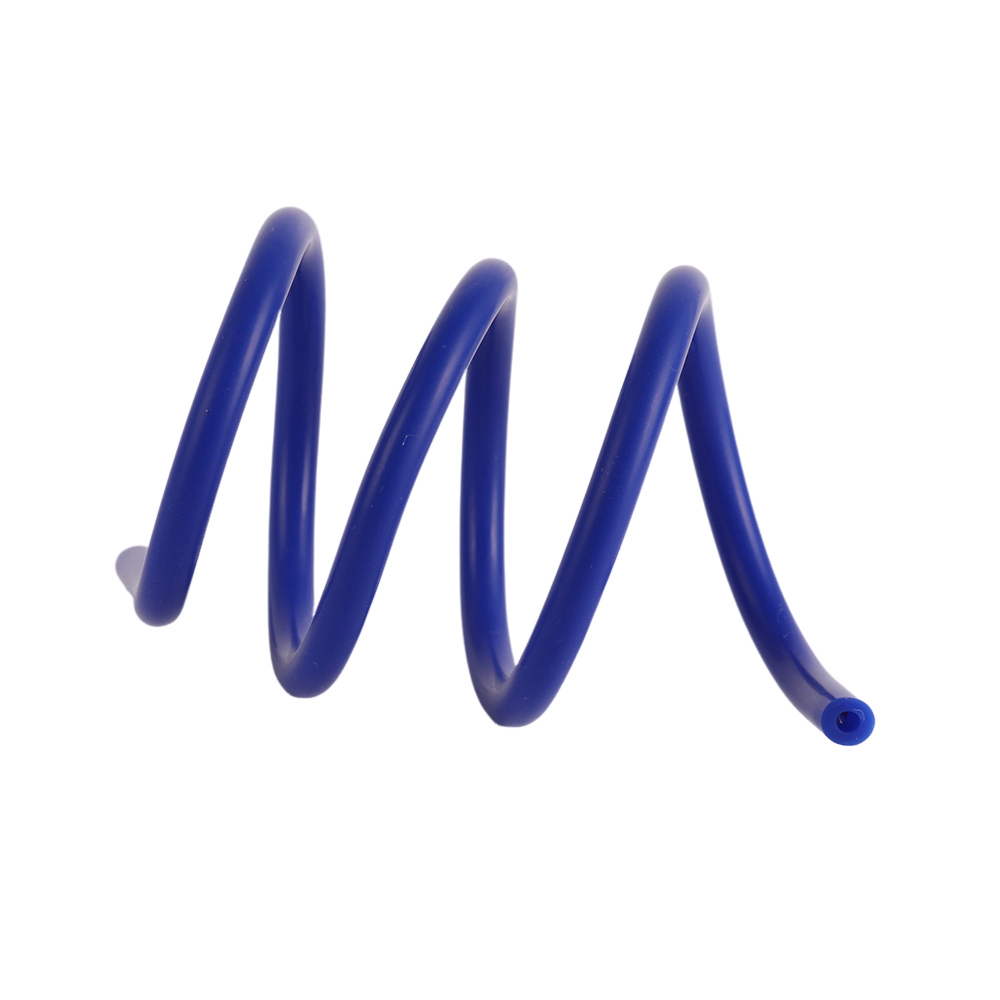

Industrial machinery components and systems with complex designs must deliver flexibility, operational durability, and high-performance standards. Under harsh operational conditions, the functioning and distribution capabilities of fluid transfer systems and air distribution depend heavily on silicone vacuum hoses.

These flexible products receive extensive industrial preference for their function in intense high-pressure, chemical exposure, and high-temperature environments.

Passion Hose is a foremost Silicone Vacuum Hose Manufacturer specializing in advanced silicone vacuum hoses for demanding industrial systems applications. The research studies how flexibility affects industrial applications by analyzing the performance of advanced system silicone vacuum hoses.

Why is Flexibility Important in Industrial Equipment?

Industrial equipment's operating conditions demand components to stretch and bend to maintain structural integrity during movement-based operations.

Operations must halt when facility workers bear significant replacement expenses after traditional rubber and PVC hoses experience mechanical stress-induced failure.

Silicone vacuum hoses remain bendable in all climate types, leading to extended operating system lifespans. Their material makes installing them simple because they can travel through tight routing without breaking.

These materials stop mechanical tension and vibration forces, reducing total system deterioration caused by wear and tear.

Industrial manufacturers achieve continuous operation through the hermetic vacuum performance of silicone tubes that operate during constant movement.

Advantages of Silicone Vacuum Hoses in Complex Systems

Resistance to High Temperatures Without Deformation

Manufacturing, food processing, and aerospace management operations must function in sustained-heat environments. Effective operation and elastic maintenance of silicone vacuum hoses occur at superhot temperatures exceeding 260°C (500°F).

Silicon hoses retain their elasticity throughout warm environments better than rubber and PVC hoses because they avoid structural breakdown.

When temperatures exceed 260°C, the material functions effectively in heating devices such as furnaces, ovens, and processing units.

Superior Chemical Resistance for Harsh Environments

Industrial facilities use silicone vacuum hoses for corrosion protection. They defend against numerous adverse chemicals and handle industrial solvents and oils.

Industries such as chemical processing, pharmaceuticals, and food production benefit from their ability to withstand exposure to acids, alkalis, and industrial solvents without degradation.

Maintaining fluid purity is essential for medical and food-grade environments because hose material shows strong chemical resistance.

Customers receive safe vacuum hoses through the manufacturing and supply services of Passion Hose, which operates as a Silicone Vacuum Hose Manufacturer under FDA and ISO certification guidelines for sensitive application needs.

Adaptability to Complex and Confined Spaces

Contemporary industrial devices that run complex circuit networks need flexible hose structures to maintain correct operations.

Silicone vacuum hoses naturally adapt their position when connecting to complicated arrangements, thus reducing the chances of hose failure and structural breaks.

Silicone vacuum hoses' functional operations require efficient flexing capabilities. When stable hose characteristics become necessary, silicone vacuum hoses can be adequately adopted into robotic arms, pneumatic systems, hydraulic systems, and medical devices.

Silicone vacuum hoses' easy installation reduces system changes while decreasing worker expenses, enabling cost-effective industry approaches.

Absorption of Vibration and Mechanical Stress

Powerful equipment vibrations rapidly destroy all materials, maintaining a rigid structure. Silicone materials protect vacuum hose system connection points and act as vibration diffusers to increase operational duration.

All manufacturing operations profit substantially from the incorporation of silicone vacuum hoses. The pneumatic, automotive, and aerospace industries deploy silicone vacuum hoses to meet operating needs that require many motion changes throughout the day.

Organizations' silicone hoses lead to longer equipment service life, lowering industrial facility maintenance expenses.

Moisture and Environmental Resistance

Silicone vacuum hoses' natural water-blocking capability protects them against moisture and humidity that can damage their internal structure.

Microbial contamination cannot penetrate these hoses due to their long-lasting water-blocking properties, which extend their functionality in food processing facilities, marine-based installations, and outdoor environments.

Silicone materials are durable because they resist UV rays and ozone in any weather that affects standard exterior products.

Applications of Flexible Silicone Vacuum Hoses in Industrial Equipment

Flexible silicone vacuum hoses operate across multiple applications because they unite high-performance attributes with adaptable design performance. Industrial hose systems use unimpeded airflow to prevent equipment breakdowns that appear when manufacturing lines, conveyor systems, and robotic arms need to operate.

The air and fluid transfer capability and pressure control allow these hoses to function in compressors, actuators, and vacuum pumps. Fluid operations can occur safely in challenging conditions because plants exhibit chemical resistance capabilities.

Food processing facilities deploy silicone vacuum hoses, which provide secure distribution of dairy products, beverages, and edible oils that fulfil necessary operational standards.

Pharmaceutical organizations depend on these hoses for transporting sterile liquids, vital for creating medical air systems in laboratories and hospitals.

The hoses follow FDA and ISO standards to deliver clean operation environments that help businesses eliminate contamination.

Choosing the Right Silicone Vacuum Hose for Your System

Your vacuum system requires a suitable silicone vacuum hose during its installation phase. The selection process for vacuum hoses depends on multiple elements, which determine their resistance to temperature changes, operating pressure admissions, physical strength, and chemical compatibility behaviour.

The operation of city pressure management requires industrial hoses that use polyester or fibreglass as reinforcing materials.

Different industries, particularly those in food services, aerospace, and pharmaceuticals, must follow specific requirements that determine their hose selection.

Passion Hose creates silicone vacuum hoses and provides them to various industrial markets, including manufacturers and suppliers.

Our company makes silicone vacuum hoses that deliver reliable service performance during extreme environments.

Maintenance Tips for Extending Hose Lifespan

The appropriate maintenance of silicone vacuum hoses is crucial for machine longevity and performance quality. Scheduled inspections can prevent system failure by helping organizations spot material deterioration, wear indicators, and leakage.

Hose operational life expectancy stays preserved when no kinks or twists exist because critical points are reduced to minimum status.

Applying a soap solution for hose cleaning removes debris and prevents material buildup, creating transparent airflow and fluid transfer capabilities.

Conclusion

Silicone vacuum hoses are used in industrial applications due to their superior elasticity, extended lifespan, and strong durability under challenging operating conditions. They are the preferred choice in the industrial sector because they resist heat, chemical harm, and mechanical pressures.

Find your reliable silicone vacuum hoses from a certified Manufacturer.

Choosing a trusted silicone vacuum hose supplier results in superior-quality, durable solutions. Passion Hose's product line offers supreme silicone vacuum hoses that meet and surpass industrial requirements for optimal performance in demanding industrial applications.

Passion Hose supplies high-performance silicone vacuum hoses as part of their broad selection of durable solutions for industrial applications.

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China