Silicone Vacuum Hoses in High-Temperature Environments: Why They Excel

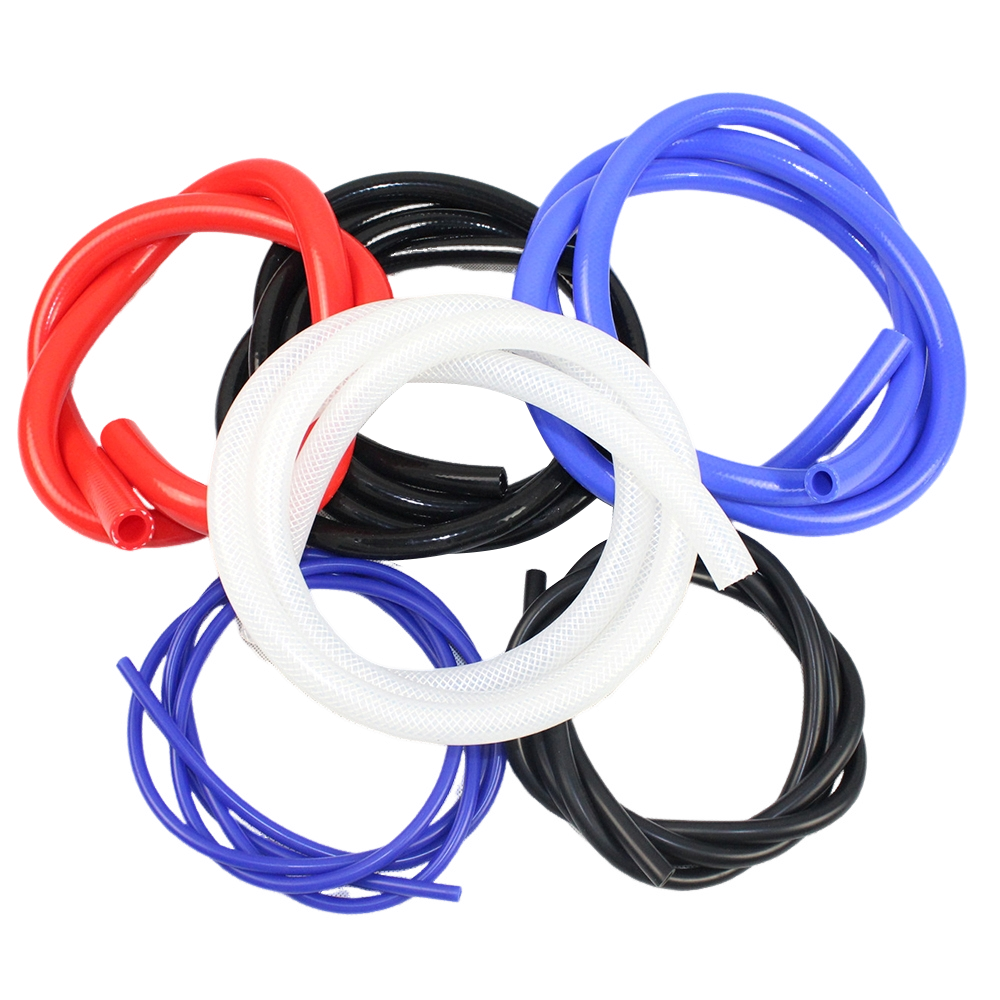

The selection of proper hoses for fluid or air transfer becomes vital in situations that entail extreme temperatures along with demanding conditions. Silicone vacuum hose manufacturers are superior to all hose materials because they possess persistent thermal properties, exceptional durability, and exceptional flexibility.

These high-performance composite hoses lead the market for applications in both automotive and aerospace industries along with manufacturing facilities thus becoming the top choice for tough temperature settings.

Passion Hose operates as a prestigious Silicone Vacuum Hoses manufacturer and supplier that provides premium silicone vacuum hoses that deliver optimal performance in severe applications.

This article analyzes why silicone vacuum hoses have superior performance in hot environments and essential factors for selection and performance evaluation. This explanation covers how industries make silicone vacuum hoses their preferred choice compared to alternative materials.

Understanding Silicone Vacuum Hoses

Modern applications need silicone vacuum hoses as specially engineered tubes that cope with intense heat together with pressure conditions and environmental challenges.

High-grade silicone elastomers form these hoses into creations that surpass rubber or PVC hoses in terms of flexibility and thermal properties while offering extended lifespans.

The automotive industry and medical sector together with the food processing and aerospace segment utilize silicone vacuum hoses because these pipes deliver effective performance when exposed to challenging conditions.

Silicone hoses meet the reliability needs of demanding applications since they resist degradation very well.

Why Do Silicone Vacuum Hoses Excel in High-Temperature Environments?

Superior Heat Resistance

The main advantage driving industries to select silicone vacuum hose manufacturers is their excellent capacity to resist high temperatures.

Standard rubber hoses show structural stability up to 150°C (302°F) but silicone hoses possess a maximum operational temperature of 260°C (500°F).

High-temperature industrial processes and engine compartments as well as exhaust systems benefit from silicone vacuum hoses because of their excellent thermal performance.

Passion Hose ensures that industries receive the highest-quality silicone vacuum hoses built to endure extreme heat conditions.

Exceptional Flexibility

The flexible characteristic of silicone vacuum hoses extends endlessly through extreme temperatures because rubber hoses degrade to brittleness.

The simple installation process combined with resistance against cracking ensures that the hose has lasting performance. Dynamic applications benefit from silicone vacuum hoses since they resist failure during multiple bending and stretching cycles.

Chemical and Environmental Resistance

Vacuum hoses made of silicone resist hundreds of chemicals as well as oils and solvents during operation. Silicone hoses demonstrate exceptional moisture resistance and they withstand oxidation and UV exposure as well as ozone exposure.

Applications operating in conditions with corrosive chemicals or extreme weather need silicone hoses because of their vital resistance property.

Durability and Longevity

Silicone vacuum hoses demonstrate life expectancy far greater than rubber hoses can achieve. The material maintains its original condition without breaking or damage throughout time in the presence of temperature changes and corrosive substances.

Passion Hose using long-lasting hose solutions benefits from silicone vacuum hoses because they reduce maintenance expenses while minimizing downtime.

Non-toxic and Safe for Various Applications

Equipment produced from Silicone serves as an undamaged material that works optimally for food processing and medical and pharmaceutical applications.

The purity of silicone vacuum hoses remains consistent because they avoid releasing toxic substances when heated since these hoses do not contaminate system elements.

Applications of Silicone Vacuum Hoses

The excellent characteristics of silicone vacuum hoses lead them to serve different industries in multiple applications.

Automotive Industry

● Silicone vacuum hoses serve within turbocharger and radiator cooling and fuel vapor recovery systems.

● Silicone vacuum hoses maintain their performance quality under elevated engine temperatures.

Aerospace and Aviation

● Essential for pneumatic and hydraulic systems in aircraft.

● Extreme altitudes coupled with fluctuating temperatures do not affect the reliable performance of silicone vacuum hoses.

Industrial Machinery

● Fluid transferred through silicone hoses operates in vacuum pumps aside from air compressors and high-temperature fluid transfer units.

● The material successfully opposes chemical harm while maintaining steady operational output.

Medical and Pharmaceutical

● This tubing serves perfectly to carry medical-grade gases together with fluids.

● The hose materials pass all safety examinations while staying free from toxic elements.

Food and Beverage Industry

● The product moves liquids together with dairy items along with other ready-to-consume materials.

● Medical and Pharmaceutical applications benefit from this product because it tolerates high temperatures without changing food and beverage preferences.

Selecting the Suitable Silicone Vacuum Hose

The selection of a silicone vacuum hose requires the evaluation of multiple factors.

Temperature Range

The hose system must demonstrate resistance to temperatures it will encounter in service. Extreme conditions fail to damage the highly durable silicone vacuum hoses manufactured by Passion Hose.

Pressure Rating

Your application requires a hose that supports pressure levels needed for operation. Silicon hoses need reinforcement elements added through multiple layers in high-pressure situations.

Inner and Outer Diameter

The correct hose dimension choices are essential for achieving both the best flow results and proper connections to existing systems. Accurate measurement will prevent compatibility problems.

Reinforcement Type

The needs of some applications require silicone vacuum hoses with internal reinforcement to achieve maximum strength and operational life expectancy. The hose walls include polyester and fiberglass strengthening elements which boost system pressure tolerance and operating duration.

Compliance with Industry Standards

Silicone hoses developed for safety compliance and performance excellence should be selected especially in medical environments along with food industries and aerospace applications.

Maintenance Tips for Silicone Vacuum Hoses

Silicone vacuum hose lifespan increases through correct maintenance procedures. These guidelines will help maximize your vacuum hose performance:

● Routine visual checks should be performed to identify signs of tears or degradation along with cracks.

● Install the hose correctly because any twisting plus kinking causes the premature breakdown of the hose.

● A mild soap mixture with water should be used for cleaning the hoses to eliminate debris and stop material accumulation.

● Hose storage should occur in a chemical-free and shaded environment with controlled temperature and dry conditions.

Conclusion

Silicone vacuum hose manufacturers act as essential industrial components because their high heat tolerance combines with their flexible structure and durable composition along with chemical-resistant properties.

Rubber hoses lose their position as top-performance alternatives when people select the superior quality of silicone hoses for their heat-intensive applications.

Your selection of a silicone vacuum hose should involve an assessment of temperature limits together with pressure limits alongside adherence to industrial standards in order to choose a suitable solution.

Working with Passion Hose as your Silicone Vacuum Hoses Manufacturer/Supplier will guarantee reliable products for your fluid transfer systems.

The time has arrived to transition to outstanding silicone vacuum hoses. Experience the perfected hose selection by visiting Passion Hose for your application needs.

Passion Hose – Your Go-To Supplier for Premium Silicone Vacuum Hoses!

The premium silicone vacuum hoses manufacturer of Passion Hose find their source at this leading Manufacturer/Supplier that focuses on quality standards for their products.

Our silicone vacuum hoses were specifically created to maintain peak operational performance under hot and difficult conditions.

The hose selection available at our company matches any requirement from automotive to industrial to medical applications. Visit Passion Hose’s PTFE Hose Collection today and take the first step towards a safer, more efficient fluid transfer solution.

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China