How Temperature and Pressure Affect Welding Hose Performance?

The pressure in welding hoses is very real. They are supposed to manage these gases safely, even in changing environments. However, temperature and pressure mainly affect a hose's performance.

A small problem with your tire or hose might result in a hose failure. That option is risky, costly and unnecessary. We'll learn in this article how temperature and pressure play a role in hose performance and how Welding Hoses Manufacturer Passion Hose builds hoses to handle hot temperatures.

How Temperature and Pressure Matter in Welding?

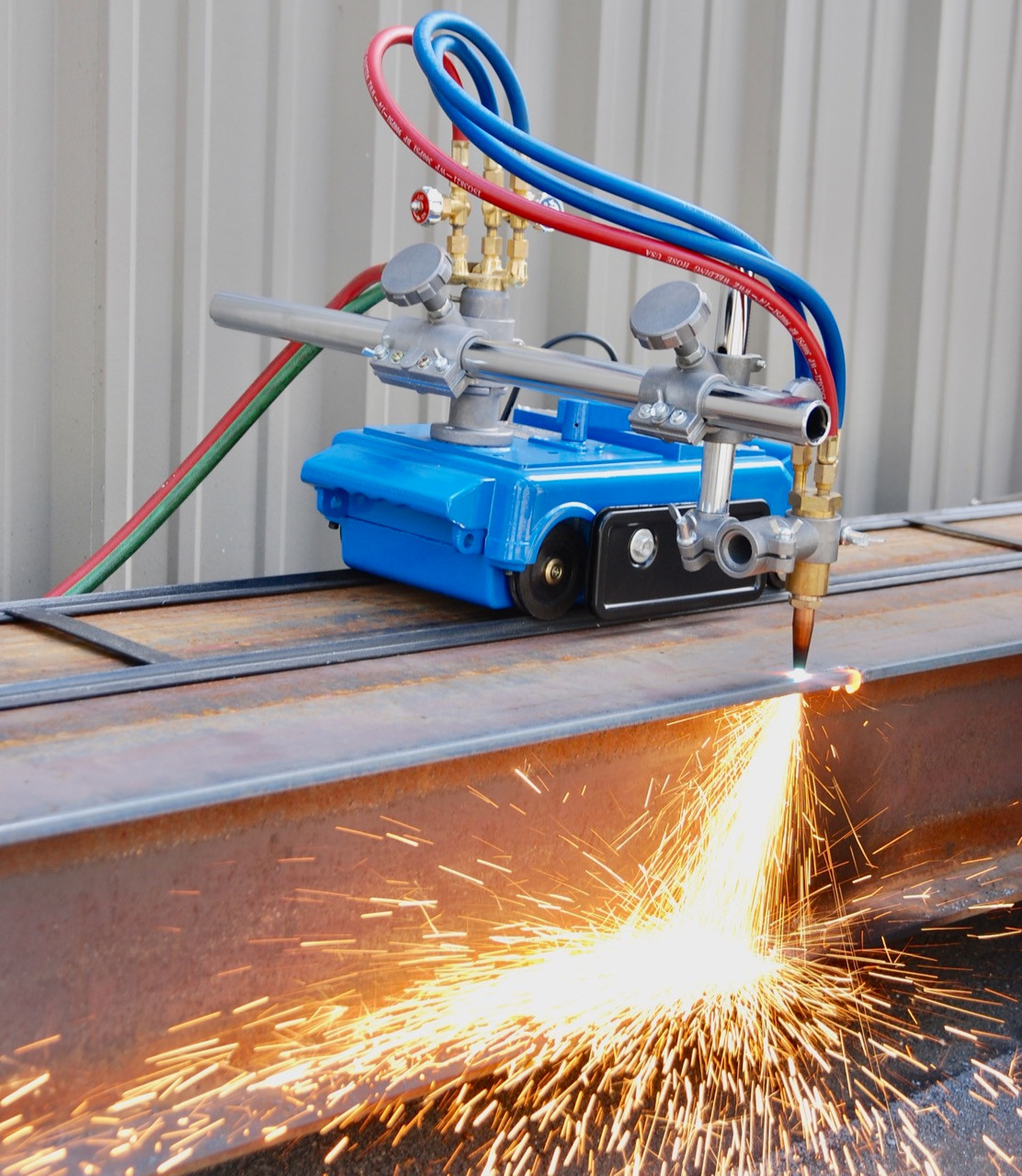

These gases, such as acetylene, propane and oxygen, are carried from the supply to the torch using welding hoses. Many of these gases move at high pressure and are put to use where temperatures may vary significantly. Rising temperatures make hoses softer. The cold causes the material to become hard and break easily. High pressure puts pressure on the inner layer of the Earth. If you have these problems together, your hose won't have much life. If a hose fails when work is being done, the results could be a gas leak, a burst or a fire. Hose safety and durability depend on understanding how temperature and pressure affect the system, making it essential to know.

Effects of High Temperature

The material is constantly under stress when a hose is used outdoors in heat or places like factories or building sites. The rubber can become softer and longer, mainly when touched by flame or radiant heat. After a period, the outer part of the hose can crack, making it less flexible. When air temperatures get higher, the air pressure in the hose can rise, too. Increased gas pressure from heat causes the hose to become even more stressed. A lack of heat resistance causes welding hoses to burst unexpectedly.

Here, it is clear that product quality is essential. Although a not-so-good hose probably won't disappoint you immediately, you are sure it won't last forever. For this reason, Passion Hose relies on strong and trustworthy compounds for any hot condition as a Welding Hoses Supplier.

The Effects of Cold

Just like your horses, welding hoses don't like to work in freezing temperatures. Doing the task in cold weather will stiffen the rubber. In such situations, hoses might crack whenever the pipe is moved or twisted. Because of hardening, pipes have less flexibility and are more likely to suffer splits or circular leaks. Always use hoses that can withstand freezing temperatures if you work on a construction site or in cold storage, because other types may become stiff and kink. A hose made for warm water may not last in colder conditions. The hoses from Passion Hose are made to keep pressure and work safely in freezing conditions. That way, workers are always protected and their work environments stay safe.

Exploring How Pressure Works and What It Does

The gas is readily available, and the related pressure plays a big part. Even some of the smallest hoses may contain highly flammable gases operating at high pressure. Hoses with thin, weak or worn material may start bulging, leaking or exploding. If the pressure is too high, the hoses will significantly elongate. The structure gets weaker, and life spans become shorter as this occurs. At its worst, a hose bursting can result in injuries or start a fire. Switching the gas on and off will also cause the appliance to wear down faster. The hose keeps expanding and contracting repeatedly. By repeating such an action, there is a risk of leaks or a surprising burst in the hose. That's why, when you buy Welding Hoses from Passion Hose, you receive pressure-tested hoses with their pressure ratings displayed. Hoses used by these companies are built with strong materials for better performance.

The Effect of Pressure + Temperature

Matters become more difficult when heat and pressure come together. Picture a summer work day taking place at a building site. Your hose sits in the sun, filled with pressurised acetylene. While the mix heats, the gas inside the mixture expands, increasing pressure within. At the same time, the rubber becomes softer. Now, both the pressure within the hose and the strength of the hose outside are reduced. Occasionally, spraying something flammable will end badly, unless the hose has been made to handle it. To deal with these challenging situations, T-grade hoses have been designed. They do not melt when exposed to heat, oil, a flame or high pressure. Instead, R and RM grades should not be used in challenging situations. Be sure that the hose grade you choose is right for where it will be used.

Selecting the Correct Hose for Your Situation

Not every hose is suited to every need. If your workplace is typical and you don't use oil with acetylene, an R-grade hose is sufficient. Gold doesn't hold up outdoors or under pressure for a long time. RM-grade hoses are more advanced but don't protect against oil or high temperatures. They work well for most domestic jobs within your home. T-grade hoses are tough, adaptable and designed for harsh environments. All of these types of fuel can be handled by these torches: propane, acetylene, butane and MAPP gas. Because they resist flames and oil, they're ideal for working in outside areas, shipyards and other industrial sites. If temperatures and pressure are involved in your work, never go lower than T-grade. You should always check the specs with the Welding Hoses Manufacturer.

Ways to Protect Your Hose from Failure

If you treat a hose carelessly, it can still malfunction. Please do not leave your hoses where they will be exposed to sunshine or close to hot machines. Always search for cracks, bulges or stiffness on the tires. Using hose reels will help you avoid weakening your hose from kinks and stress. It is also essential to clean your backyard. Just use a gentle soap and water. Do not apply concentrated chemicals to your lawn if your hose is not rated. Moisture can become trapped inside plastic-wrapped oil-resistant hoses, so avoid putting them in plastic. Caring for your hose can nearly double its working life. It ensures your data is protected and your costs are kept down.

Why You Need a Good Quality Hose Supplier

The importance of a good hose isn't limited to rubber. Manufacturers want a solid construction, products that are tested and products people trust. This is when your Hose Supplier can genuinely help you. Passion Hose emphasises supplying top-quality hoses tracked from beginning to end. Various temperature and pressure combinations are used when testing each batch. This means that along with your hose, you receive paperwork proving it can do what it claims. Safety matters greatly when compliance must be met, and having an ID is very important.

Final Thoughts

Safe welding hoses are made differently from unsafe ones due to exceptional attention to temperature and pressure. Select a hose that matches the particular conditions at your worksite. R-grade and RM-grade hoses should only be used in the proper conditions. For those moments when you need more strength, T-grade straps will help. It is also important to remember: A trusted Welding Hoses Supplier will suggest the right product, with details on its production and its uses.

On the lookout for tireless welding hoses?

Contact us at Passion Hose, your expert manufacturer/supplier of Welding Hoses, when you want to find the best hose for your heat and pressure level. Whether conditions are cold, hot or very pressured, they'll give you a trustworthy hose that has a longer lifespan.

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China