Applications of Silicone Vacuum Hoses in Industrial Equipment and Machinery

Factory machines need robust parts that deliver superior performance for uninterrupted functioning. The transfer of fluids and air through silicone vacuum hoses stands as a critical function in settings that face intense heat changes and pressure changes as well as chemical exposure.

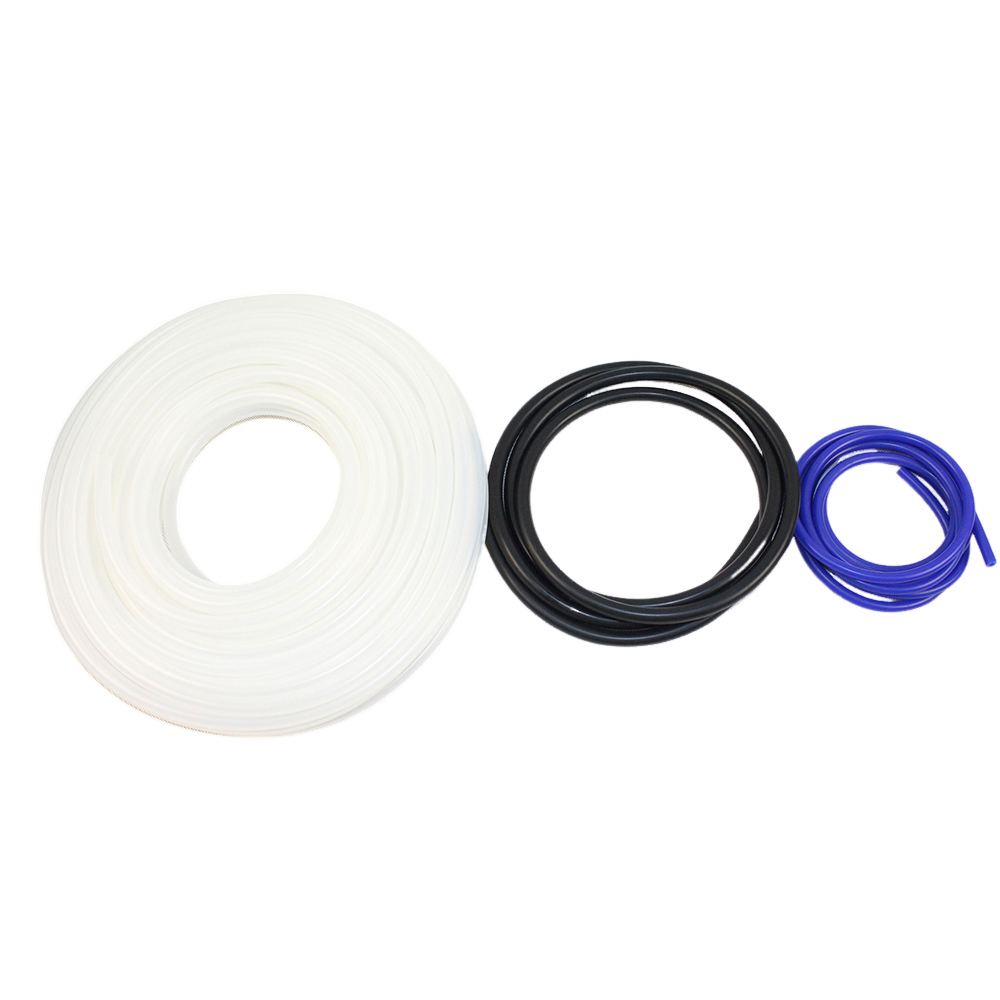

The flexible nature together with heat tolerance and extended lifespan of silicone vacuum hoses makes them suitable for diverse industrial requirements when instead of rubber or PVC hoses.

Passion Hose operates as a leading Supplier of Silicone Vacuum Hoses and develops durable hose products for industrial equipment and machinery. The article demonstrates how these hoses serve critical purposes across industrial uses through evaluations of their fundamental importance.

Why Are Silicone Vacuum Hoses Vital for Industrial Equipment?

Hoses intended for extreme industrial applications need to handle heat with chemical substances and mechanical wear throughout time without losing performance.

Civil engineering plants and chemical processing units along with high-temperature machinery depend on silicone vacuum hoses because they maintain continuous operations better than standard hose materials.

These hoses function successfully at temperatures exceeding 260°C (500°F) because of which they serve best in tough industrial settings. Silicone vacuum hoses demonstrate exceptional flexibility so manufacturers can install them effortlessly in intricate machinery because they do not break or crack.

The exceptional chemical oil and solvent resistance property of silicone vacuum hoses allows them to endure corrosive environments effectively. Silicone vacuum hoses serve industries best since they deliver exceptional hose performance and durability in demanding operational environments.

Applications of Silicone Vacuum Hoses in Industrial Equipment

Manufacturing and Production Lines

The production processes in manufacturing facilities depend intensively on vacuum-powered machinery together with automated systems for their streamlined operation.

Silicone vacuum hoses enable efficient airflow and fluid transfer through their functionality which leads to reduced system failures along with lower maintenance expenses.

The hoses resist changes in pressure and mechanical stress which enables their use in processing equipment such as conveyors, robotic arms, and assembly lines.

Pneumatic and Hydraulic Systems

Pneumatic and hydraulic components in industrial machines need hoses that must support continuous pressure handling operation. Highly flexible and pressure-resistant systems utilize silicone vacuum hoses as their reliable choice of solution.

These hoses prove beneficial to industries that operate compressors, vacuum pumps, and actuators because they provide effective leak prevention along with operational efficiency maintenance.

High-Temperature Processing Units

The application of silicone vacuum hoses becomes crucial for industries that need heat-intensive processing operations. Many industrial oven systems, furnace equipment, and smelting units expose standard hoses to high temperatures which cause gradual degradation.

Under intense thermal conditions silicone hoses maintain peak operation by preserving their structural form while continuing to transfer air fluids and gases without failure.

Chemical and Industrial Processing Plants

Industrial chemical processes need hoses to withstand contact with damaging chemicals as well as toxic agents and liquid solvents. Silicone vacuum hoses display outstanding chemical resistance which protects them from the degenerative effects of acids and alkalis as well as industrial solvents.

Silicone vacuum hoses function perfectly in dangerous fluid transfer settings as well as hazardous gas handling applications because of their moisture resistance. The hose systems enable industry facilities to meet security requirements together with extended operational stability.

Food and Beverage Industry

Production facilities that prioritize hygiene and safety need food-grade silicone vacuum hoses as their primary component. Silicone vacuum hoses provide broad usage in dairy operations alongside beverage manufacturing along with edible oil transfers to establish contamination-free liquid movement.

Such hoses exist perfectly for food and beverage processing operations because they stay unaltered under elevated temperatures.

Pharmaceutical and Medical Manufacturing

The pharmaceutical industry and medical field employ silicone vacuum hoses for their use in sterile fluid serta gas transfer systems. The materials uphold FDA and ISO regulatory security requirements which confirms they release no dangerous components or toxic materials.

The industries that utilize this material for purity needs include biotech laboratories as well as medical-grade air systems and pharmaceutical production units.

Benefits of Using Silicone Vacuum Hoses in Industrial Machinery

Silicone vacuum hoses have become the standard industrial choice because they provide excellent reliability together with outstanding durability. The combination of heat-resistant capabilities together with chemical resistance and flexibility spans their operational lifespan which lowers maintenance expenses.

The use of superior hoses sourced from Passion Hose's Silicone Vacuum Hoses Manufacturer enables industries to prevent breakdown expenses while reducing maintenance spending.

Silicone hoses provide a safe solution in food and pharmaceutical as well as medical device applications because they remain both environmentally safe and non-toxic over time. Silicone hoses offer excellent durability as they avoid performance degradation over time and thus provide a cost-effective extended service life to industrial requirements.

How to Choose the Right Silicone Vacuum Hose for Industrial Use?

The process of selecting appropriate silicone vacuum hoses demands investigators to weigh performance attributes consisting of temperature resistance capability and pressure capacity alongside diameters of inner and outer elements and reinforcement requirements.

Some applications demand reinforced hose structures with polyester or fiberglass additions to handle elevated pressure requirements.

The hoses must fulfill all required industrial standards especially when used for applications in food processing pharmaceuticals and aerospace production.

Your purchasing of silicone vacuum hoses at Passion Hose establishes your access to products that comply with industry standards and necessary performance levels.

Maintenance Tips for Prolonging Hose Lifespan

Proper maintenance protocols provide industries with the best way to extend the performance lifetime of their silicone vacuum hoses.

The lifespan of silicone vacuum hoses becomes longer when inspections are performed regularly because these inspections detect early warning signs of wear and leakage. Kinks and twisting during installation should be avoided because they result in early failure of the hoses.

A solution of mild detergent used to clean hoses eliminates debris while stopping material buildup which ensures unimpeded airflow together with fluid transfer processes.

Storing these silicone hoses must be done in dry controlled temperature areas isolated from both sunlight exposure and chemical substances to preserve their structural quality.

Conclusion

The industrial sector relies on silicone vacuum hoses as essential components of machinery because they present exceptional durability alongside both flexible operation and strong resistance to harsh environments.

Manufacturing operations along with chemical processing, food production, and pharmaceutical applications adopt silicone solutions because these products deliver excellent performance and reliability.

Everyone in the market for Silicone Vacuum Hoses should select their manufacturer or supplier very carefully to achieve maximum cost-effectiveness and extended performance lifetime.

The factory at Passion Hose creates resistant silicone vacuum hoses with first-class materials that thrive in demanding industrial settings.

Get High-Performance Silicone Vacuum Hoses for Your Industrial Needs

Industrial activities depend on components that offer dependable service while resisting heat intensity to deliver unimpeded operational performance. The focus of Passion Hose remains to produce top-tier silicone vacuum hoses that excel against extreme temperatures and chemical exposure as well as mechanical stress elements.

Industrial operations can rely on our high-quality solutions for reliable hose delivery across manufacturing facilities as well as chemical processing plants, food production sites, and pharmaceutical applications.

Your industrial equipment demands superior quality elements thus select an established Silicone Vacuum Hoses Manufacturer. Contact Passion Hose now to view our full collection of high-performance silicone vacuum hoses that fulfill customized requirements.

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China