A Rainbow of Functionality: Unveiling The Significance Of Rubber Hose Colors

Rubber hoses are essential in various industries, facilitating the transport of liquids and gases in an efficient and controlled manner. However, in addition to their functional role, the color of rubber hoses can provide critical information, improving safety, efficiency and convenience, we explore the importance of rubber hose colors and how they contribute to functionality.

Why Do Rubber Hoses Come in Many Colors?

Safety and Identification

Different colors help in quickly identifying the purpose and content of the hoses, reducing the risk of accidents and ensuring the correct usage. For example, blue hoses may be designated for cold water, while red hoses might be for hot water.

For Separation in the Water Lines.

A red hose pipe carries hot water.

A blue hose pipe carries cold water.

Compliance with Industry Standards

Many industries have regulations that require color coding to ensure safety and compliance. This helps prevent misuse and promotes a safe working environment.

Regulatory Compliance: In many regions, there are regulations that require gas pipes to be easily identifiable by color. Orange is commonly chosen for its distinctiveness and universal recognition as indicating the presence of gas lines.

Standardization: Standardizing the color of gas pipes to orange ensures consistency across different utility companies and regions. This reduces confusion and improves safety for workers and the public.

Gas Cutting Hose Pipe Color Code.

Branding and Aesthetics

Colored hoses can enhance brand recognition and improve the visual appeal of an industrial environment. Companies often choose colors that match their brand image.

Paishun Brand Hose Photo.

Functional Benefits

The color of a hose can indicate its material composition and suitability for specific applications, ensuring optimal performance. For instance, certain colors may signify UV resistance or high-temperature tolerance.

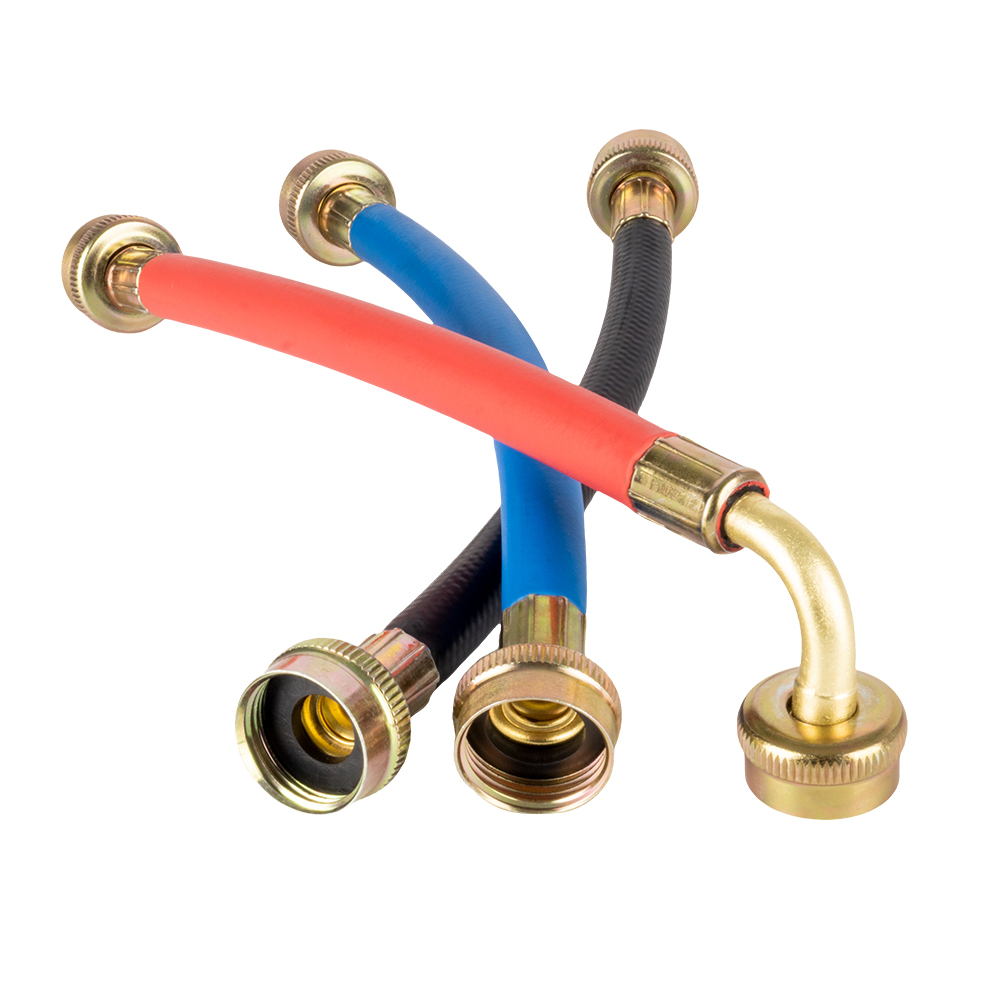

In refrigeration systems, the colors of refrigerant charging hoses—red, yellow, and blue—have specific applications:

Red Hose: Typically used for the high-pressure side of the system, also known as the discharge or liquid line.

Yellow Hose: Commonly used for charging or adding refrigerant to the system and can connect to both high and low sides.

Blue Hose: Used for the low-pressure side, also called the suction line.

These color-coded hoses help technicians quickly identify their functions and ensure proper usage.

Operational Efficiency

Color-coded hoses facilitate quick identification and selection, improving operational efficiency and reducing downtime, this is especially important in large-scale operations where speed and accuracy are critical.

By utilizing a variety of colors, rubber hoses contribute to safer, more efficient, and visually appealing work environments.

● Zoe Wei

● WhatsApp: +86 137 3809 5094

● Email: ps04@parshun.com

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China