In the demanding world of hydraulic systems, the integrity and performance of hydraulic hoses are non-negotiable. A common yet overlooked issue is the pinching of hydraulic hoses, leading to decreased efficiency, potential leaks, and even system failures. As a leading hydraulic hose manufacturer, Passion Hose is dedicated to not only providing top-quality hoses but also educating our clients on how to prevent such problems.

This blog will guide you through essential tips and best practices to keep your hydraulic hoses in optimal condition, ensuring they remain unpinched and functional for the longest time possible. Join us as we explore the preventative measures and solutions offered by Passion Hose.

Understanding the Risks of Pinched Hydraulic Hoses

Pinched hydraulic hoses can significantly compromise the efficiency and safety of your hydraulic systems. When hoses are pinched, they are subject to increased wear and tear, which can lead to premature failure. The pinching typically occurs due to improper routing, inadequate space, or mechanical forces exerting undue pressure on the hose. This can result in restricted fluid flow, leading to a drop in performance and potentially causing the hose to burst under high pressure. Understanding these risks is the first step in preventing them, and ensuring the longevity and reliability of your hydraulic systems.

Best Practices for Preventing Pinched Hoses

Preventing your hydraulic hoses from getting pinched is crucial for maintaining system integrity and functionality. Here are some best practices:

● Proper Routing: Ensure hoses are routed away from sharp edges and corners where they can become pinched or abraded. Maintain a sufficient bend radius to prevent kinking and pinching.

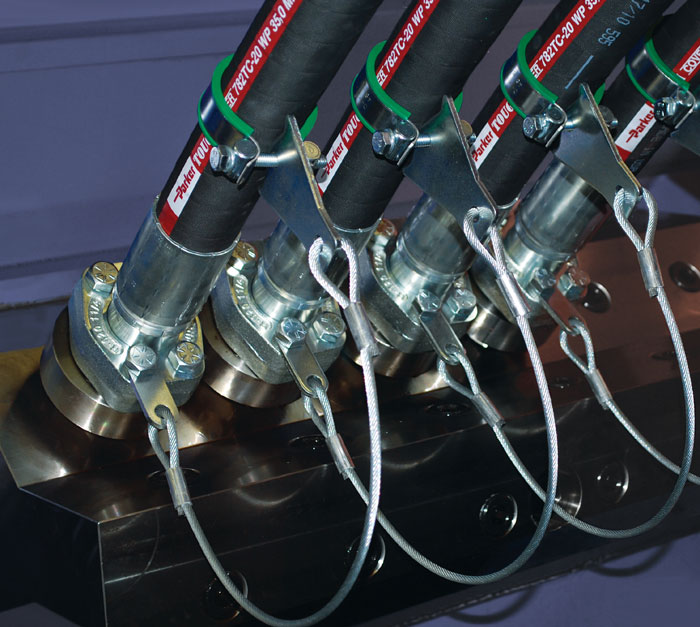

● Secure Clamping: Use appropriate clamps to secure hoses in place. This prevents excessive movement that could lead to pinching or abrasion.

● Regular Inspections: Regularly inspect hose assemblies for signs of wear, kinking, or pinching. Early detection can prevent more severe issues down the line.

● Correct Installation: Ensure that hoses are not twisted during installation, as this can weaken the hose structure and lead to pinching or failure.

By following these practices, you can significantly reduce the risk of your hoses getting pinched, thereby extending their life and maintaining system efficiency. Passion Hose's quality hydraulic hoses are designed with these considerations, offering durability and reliability for various applications.

Regular Maintenance and Inspection

Regular maintenance and inspection are key to preventing hydraulic hoses from getting pinched and other common issues. Here's what you should focus on:

● Visual Inspections: Regularly examine the hose for any signs of damage, such as cuts, abrasions, or unusual bending. Pay special attention to areas where pinching is more likely to occur.

● Pressure Checks: Monitor the hydraulic system's pressure. Sudden pressure drops might indicate a pinched or leaking hose.

● Environment Checks: Ensure the operating environment hasn't changed in a way that could affect the hoses. For example, check for new contact points where hoses might get pinched.

● Replacement Schedule: Adhere to a regular replacement schedule based on the manufacturer's recommendations and the operating conditions.

By incorporating these maintenance and inspection practices, you can significantly extend the life of your hydraulic hoses and prevent unexpected system downtimes. Passion Hose is committed to providing products and the knowledge you need to maintain them, as seen in our comprehensive maintenance tips.

The Role of Quality Hydraulic Hoses

Choosing high-quality hydraulic hoses from reputable manufacturers like Passion Hose is a critical step in preventing pinching and other issues. Quality hoses are designed with superior materials and construction techniques to withstand the rigors of hydraulic systems. They offer:

● Enhanced Flexibility: Reducing the likelihood of kinking and pinching under pressure.

● Durable Construction: Resisting wear, abrasion, and environmental factors that can lead to damage.

● Optimal Fitting Design: Ensuring a secure connection and minimizing the chance of misalignment or loosening that could pinch the hose.

Investing in quality hoses from Passion Hose means investing in the longevity and reliability of your hydraulic systems, ensuring they operate smoothly and efficiently.

Custom Solutions for Unique Systems

Every hydraulic system has its unique challenges and requirements. Passion Hose understands this and offers custom solutions to fit your specific needs. Whether you're dealing with tight spaces, unique angles, or specific pressure requirements, we can provide hoses and fittings tailored to your situation. Our team works closely with you to understand your system's intricacies and develop solutions that prevent pinching and other issues. With Passion Hose's custom solutions, you're not just getting a product; you're getting a partner dedicated to your system's success.

Conclusion

Preventing hydraulic hoses from getting pinched is crucial for the safety, efficiency, and longevity of your hydraulic systems. By understanding the risks, following best practices, conducting regular maintenance, choosing quality hoses, and opting for custom solutions when necessary, you can protect your hoses and your system. Passion Hose is here to provide the products and expertise you need every step of the way.

Ready to Enhance Your Hydraulic Systems? Connect with Passion Hose Today!

Don't let pinched hoses disrupt your operations. Visit Passion Hose today to explore our range of high-quality hydraulic hoses and learn more about how we can help you keep your systems running smoothly. Contact us for personalized advice and solutions tailored to your specific needs. Let's work together to ensure your hydraulic hoses are always in top condition!