How to Cut Automotive Hose Like a Pro

Meta Description: Looking to cut automotive hoses like a pro? Our step-by-step guide will help you discover the secrets to achieving clean and accurate hose cuts.

Are you wrestling with an automotive hose that just won't conform to your needs? Perhaps it's too lengthy for your car project, and you're wondering the best way to trim it down.

If you're the kind of automotive enthusiast who enjoys hands-on work, making custom intercooler pipe couplers, or seeking that perfect fit for your vehicle, I bet you have.

And you are right! Getting it right can be the difference between a seamless installation and a frustrating setback.

In this blog, we'll look into automotive hose cutting, sharing tips and techniques to help you tackle this task like a pro. Whether you're a seasoned DIY mechanic or just getting started with automotive projects, you'll discover the secrets to achieving a clean, precise cut every time.

But a few tips first…

Understanding Automotive Hoses

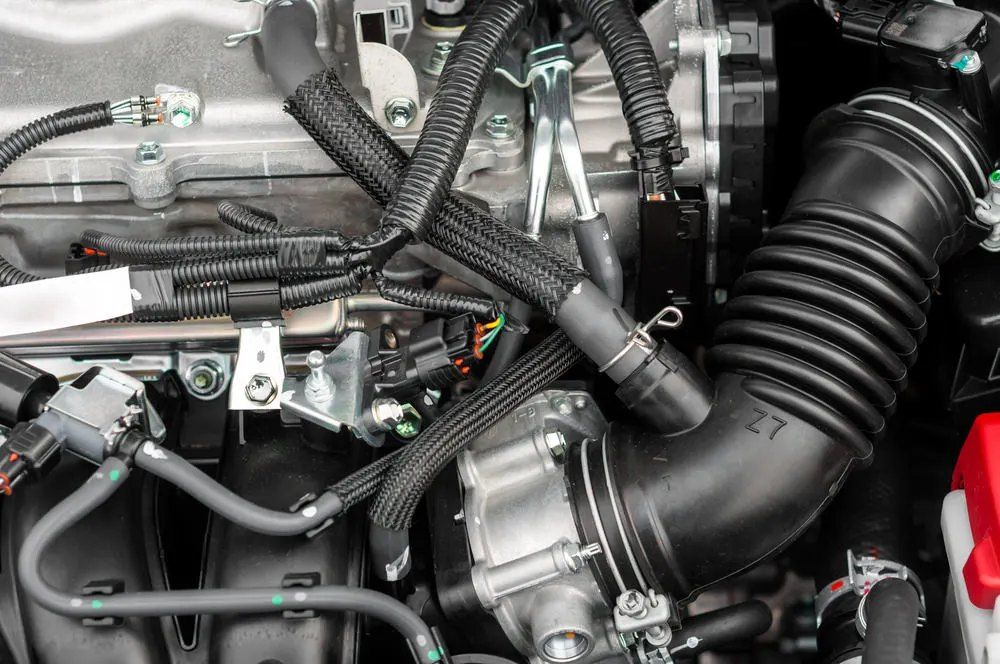

Although automotive hoses come in various shapes and sizes, they all have one thing in common: the vehicle’s plumbing system.

From radiator hoses to fuel lines, they are responsible for transporting fluids and gases, making them a crucial part of your car's functionality.

Types and Materials

Before we jump into cutting, let's get familiar with the different types and materials of automotive hoses you might encounter.

We've got rubber hoses, silicone hoses, and more. Each has its strengths and specific applications.

Common Applications

Now, where do these hoses come into play? Think about your car's cooling system, fuel delivery–and even brakes. Yep, hoses everywhere, ensuring your vehicle runs smoothly.

Importance of Precision

Here's the kicker: precision is everything when hose cutting. Why, you ask? Well, imagine a hose with a jagged, uneven cut. It's like trying to sip a beverage from a cup with a chipped rim—messy and inefficient, right?

Accurate hose cuts prevent leaks, enhance performance, and ensure safety on the road.

Tools and Equipment

Before we get into the nitty-gritty of cutting automotive hoses, let's ensure you have the essential tools at your disposal.

Here are the tools you'll need:

1. Hose Clamp: This will help secure the hose while you work.

2. Sharp Cutting Tool: Depending on the hose diameter, you can use a razor blade, box knife, or hose cutter.

3. Ruler or Tape Measure: Precision starts with accurate measurements. Measure twice, cut once, as they say.

4. Safety Gear: Safety first, always. So, remember safety gloves and goggles to protect your hands and eyes during the cutting.

5. Marker or Chalk (optional): These can be handy for marking the cutting point.

And here's a pro tip: Maintain your cutting tools. A well-kept tool ensures cleaner cuts.

Step-by-Step Guide To Make a Precision Cut

Follow the steps below to cut your hose.

Step 1–Measure and Mark

Begin by measuring the required length of the automotive hose you intend to cut. Use a tape measure or ruler to ensure accuracy. If necessary, mark the cutting point on the hose with a marker or chalk to provide a clear reference for your cut.

Step 2–Safety First

Before cutting, it's essential to ensure the hose is free of any pressure or fluid flow. Follow the manufacturer's guidelines to drain any fluids or relieve pressure from the system. Safety is paramount, so wear safety gloves and goggles to protect yourself from potential accidents.

Step 3–Choose the Right Cutting Tool

The choice of cutting tool depends on the diameter and type of automotive hose you're working with:

● Unreinforced Small-Diameter Hoses (Up to 8mm): You can use wire cutters, pliers, or scissors to cut.

● Small-Diameter Reinforced Hoses (Up to 25mm): For these hoses, we recommend a sharp blade or parcel knife for precise cuts. Make sure your blade is brand new or sharp enough for clean results.

Step 4–The Cutting Process

● Secure the Hose: Place your hose firmly in a stable position, ensuring it won't move during cutting. If possible, use a vise or clamp to hold the hose securely. This helps maintain stability and ensure a straight cut.

● Cut: Apply steady pressure and cut the hose in a straight, smooth, continuous line. Avoid applying excessive force or sawing action, as this can result in an uneven or jagged cut.

Step 5–Inspect Your Cut

After completing the cut, carefully inspect the end of the hose to ensure it's clean and even cut. Check for any frayed or uneven edges that may affect the hose seal and connection. If you notice any uneven edges, don't worry; it's a common occurrence. You can use a deburring tool or sandpaper to smooth it out.

From here, you can connect your hose and test for leaks. Use hose clamps or other fastening devices, if necessary, to ensure a secure connection and prevent leaks.

Cutting Automotive Hoses FAQs

We know you have some burning questions. Let's address them.

What types of hoses are commonly used in automobiles?

Automotive hoses vary, but you'll often find radiator hoses, fuel hoses, and vacuum hoses.

How do I measure the length of the hose I need?

Measure from end to end, following the path the hose will take, and add a bit of extra length for flexibility.

Can I reuse cut-off hose sections?

We do not recommend it. While you can technically reuse them, it's best to use fresh, uncut hose sections for optimal performance.

Conclusion

There you have it! Cutting automotive hoses like a pro is all about precision, the right tools, and a touch of know-how. So, start your automotive projects knowing you can handle hose cutting like a seasoned mechanic.

Ready for more automotive maintenance insights? Explore our other guides.

You can also explore our extensive selection of automotive hoses on our product page. You can find high-quality hoses that meet your specific needs for your project there. Be it silicone hoses, rubber hoses, or any other type, we have you covered.

For inquiries or custom orders, contact us at +86-571-81023091. You can reach us 24/7, and we are always here to help.

Passion Hose founded in 2007, a professional silicone hose manufacturer, a brand of pipeline hose and accessories R&D, production and sales. Main products: stainless steel shower hose,hydraulic hose, industrial hose, automotivehose, plumbing hose etc., which are widely used in home, hotel, industry and other fields.

Quick Links

Products

If you have any question, please contact us.

Email: ps1@passioncohose.com

Tel: +86-136-6663-2043

Whatsapp: +86-13666632043

Add: B-101, Hangzhou Smart Industrial Park, No. 857, Wenyixi Rd. Hangzhou, 310030, China